Materials:CVD diamond ,natural diamond

Classfactions:single point diamond dressing tools,multi-point diamond dresser,forming diamond dresser

Specifications: customized according to drawings

Applications:Truing and dressing grinding wheel including general grinding wheel and super abrasives grinding wheel

The grinding wheel dressing process is an important part of the grinding process. The main purpose is to remove passivated abrasive particles, improve the sharpness of the grinding wheel, improve the concentricity or shape the profile of the grinding wheel.

Moresuperhard diamond dressing tools are mainly used for semi-fine grinding and finishing dressing of CNC grinding machines, ordinary cylindrical grinding machines, centerless grinding machines, and surface grinding machines. High-quality strip-shaped diamond is used as raw material. There is no need for sharpening and repairing during use, and the diamond can be completely consumed. The self-owned surface polishing technology makes the polished diamond have excellent smoothness and extremely low friction coefficient, and has excellent chip resistance. , The surface roughness of the processed workpiece is close to the processing effect of natural diamond.

Mainly Three Types Of Diamond Dressing Tools

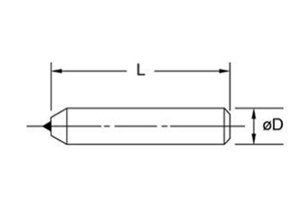

Single point diamond dressers

Application:dressing straight type conventional abrasive wheels. Dressing ceramic abrasive SG grinding wheels ,simple profiles, thread and gear grinding

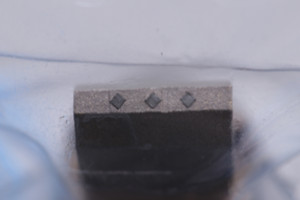

Multi-point diamond dressing tools

3 point diamond dresser

Application: large OD wheels, surface and centerless grinding wheels.It is used for auto parts, mould industry,and other precision machinery parts industry

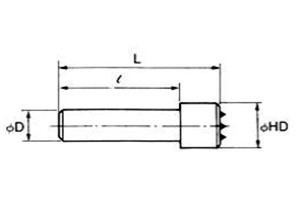

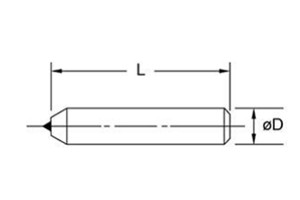

Forming diamond dressers

Application: dressing specific forms into conventional abrasive wheels(formingarc, angle, groove radius and other complex profiles) .

Two types of forming diamond dressers: chisel type and cone type.

Characteristic

1.The diamond wears evenly and does not need to be sharpened. It is suitable for dressing all kinds of conventional abrasive wheels.

2.Allows higher individual feed rates and exhibits longer service life.

Diamond dressing tools using tips

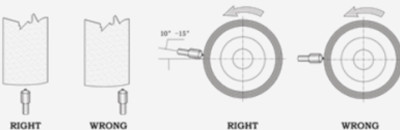

Diamond dressor is generally used for dressing traditional grinding wheels. When using, we should pay attention to that the dressor and grinding wheel keep an Angle of 10 to 15 degrees, while the grinding wheel keep counterclockwise rotation.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Polyetheretherketone PEEK has excellent comprehensive properties and can replace traditional materials such as metals and ceramics in many special fields. Moresuperhard has developed targeted grinding wheel formulas for the grinding of special engineering plastics such as PEEK, mainly electroplated grinding wheels, divided into rough grinding and fine grinding.

Diamond peripheral grinding wheels are used for peripheral grinding of PCD, CBN, carbide, ceramic, cermet and other indexable blades, flat blades, milling cutters, cutting blades, brazing blades, and machine clamp blades. At present, Moresuperhard peripheral grinding wheels have been successfully equipped with domestic and foreign mid-to-high-end peripheral grinding machines such as Hypertherm, Tiantong, Weize, WAIDA, EWAG, AGATHON, and WENDT, and have received unanimous praise from customers.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088