News

Home / News / Industry News > CVD Diamond Deposition Technology

After nearly 20 years of development, CVD diamond preparation technology has made great progress in quality, size and growth efficiency of diamond. In addition to the following four growth technologies, there are flame CVD technology, microwave ECRCVD technology and RF plasma CVD technology, etc. At present, practical growth technologies mainly include: hot wire CVD, microwave plasma CVD, dc plasma injection, CVD hot cathode dc glow plasma CVD production technology.

Hot-filament CVD diamond growth technology is the most classical growth technology. The characteristic is the equipment one-time investment is little, has the advantage of simple operation, easy control and so on. The maximum growth area is 200 ~ 300mm in diameter. However, due to the low active components in the gas, the inability to add oxygen and the problem of hot wire contamination, the hot-filament CVD growth technology is difficult to prepare high-purity diamond film. Diamond film prepared by hot wire CVD technology is mainly used in wear - resisting, cutting, grinding tools and other machining fields.

In recent years, the development of microwave plasma CVD technology is fast, the power is more than dozens of kilowatts, the superiority is more and more obvious. The plasma produced by microwave discharge has the advantages of high energy and no impurity source. In the process of growth, a small amount of oxygen can be added to further improve the removal rate of graphite in the process of deposition. Microwave growing equipment is mainly used to prepare diamond film materials with high technology such as optical level, dielectric level and even single crystal epitaxy.

The technology is characterized by fast growth and large gas consumption. The basic principle is: in a certain gas environment, the hot plasma activation reaction gas generated by dc electric arc discharge is used to generate diamond film. As the temperature of the hot plasma can be as high as 5000K, the concentration of atomic hydrogen is higher than that of the hot wire and microwave CVD methods.

This technology USES dc glow discharge to produce plasma, the matrix is placed in the anode, and the cathode is heated by ion bombardment to produce diamond film.

Different deposition processes are required for different applications, which can be generally divided into optical diamond film process, mechanical diamond film process, low-temperature deposition process, coating process, doping process, heteroepitaxy process, single-crystal diamond film process and nano-diamond film process. The most commonly used equipment in the research of these processes is the microwave CVD diamond equipment.

Optical grade diamond film has excellent properties of wide band transmission, low medium loss, high thermal conductivity, high hardness and chemical stability, so it is an ideal window material. The preparation of optical grade diamond film requires high plasma ionization density, usually using high-power microwave CVD equipment, low carbon concentration, accurate control of matrix temperature, a small amount of oxygen, good vacuum sealing system, high gas purity. Diamond film has large grain size. Low growth rate.

Mechanical grade diamond film has high strength and is opaque to light. The growth process condition is stable, the carbon concentration is high, the growth grain is fine.

In order to avoid the damage of high temperature to the structure performance of matrix during diamond film deposition, microwave CVD and addition of oxygen were used to lower the deposition temperature up to 350℃.

CVD diamond coating technology is mainly used in machining, especially in the application of cutting tools with complex shapes such as drill bits. The basic structure is to deposit diamond film of several microns to dozens of microns on the matrix material (usually hard alloy), with small grain size and low roughness. Hot-filament CVD technology is generally used.

Diamond film doping technology and epitaxy technology, which are necessary for semiconductor application, have been important issues attracting people to study.

Monocrystalline diamond film is first necessary for semiconductor applications. However, due to the high surface energy of diamond nucleation, it is difficult to achieve heteroepitaxy on silicon monocrystalline. Now, many laboratories try to deposit high-directional diamond film on the surface of monocrystalline silicon (100) in order to obtain a large area of monocrystalline diamond film. The key processes are surface treatment and nucleation control.

Nano-diamond film not only has the hardness of ordinary diamond film, but also has a smooth surface (about Ra20nm), without polishing. It has a good application prospect in MEMS, wear-resistant coating and other fields. A variety of nano-diamond film deposition processes have been reported in the general literature, but it should be noted that hydrogen-based processes cannot be called nano-diamond film processes, because when the film thickness increases (greater than 1 micron), the grain size increases by more than 1 micron. The typical nano-diamond film process is the microwave argon CVD process invented by professor Dieter Gruen of Argonne national laboratory, USA, with 99% argon 1% CH4, matrix temperature 700 ℃, and pressure 13300Pa.They called the diamond film UNCD (ultra-nanocrystalline diamond films).

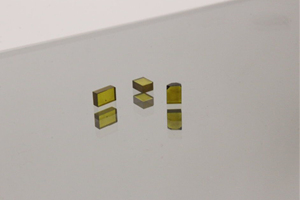

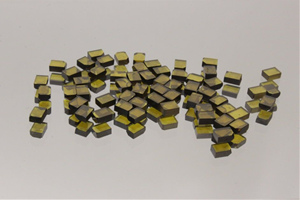

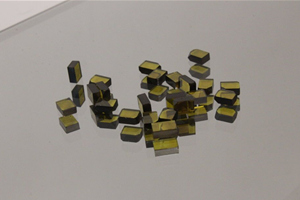

<< Prev Article:PCD&PCBN inserts

<< Next Article:Difference between PCD Tools and CBN Tools

Vitrified bond diamond grinding wheels possess pretty high a...

Our company mainly develops a new making holes’ method for P...

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220