What is cermet materials?

Cermets are structural materials composed of a ceramic hard phase and a metal or alloy binder phase. From the English word Cermets of metal ceramics, it is composed of Ceramic (ceramic) and Metal (metal). Cermet not only maintains the high strength, high hardness, wear resistance, high temperature resistance, oxidation resistance and chemical stability of ceramics, but also has good metal toughness and plasticity.

The characteristics of cermet tools:

(1) high hardness;

(2) low affinity with the workpiece material to be processed, not easy to produce built-up edge;

(3) good chemical stability;

(4) good heat resistance and wear resistance.

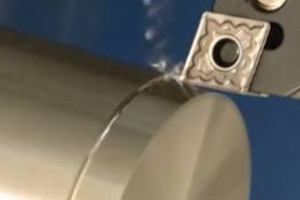

Cermet tools Suitable processing range:

Cermet cutting tools are suitable for semi-finishing and finishing machining of various steel and cast iron parts. When the cutting depth is below 2.5mm, the feed rate per revolution is below 0.25mm/r, and the feed rate per tooth is below When the diameter is less than 0.2.mm/tooth, the cermet cutting tool has excellent cutting performance. Cermet tools for processing the above materials can provide stable tool life and good surface finish. However, it is not suitable for cermet tools in the field of intermittent cutting, and the blade is prone to breakage.

Using cermet cutting tools Note:

In terms of the hardness of processing materials, cermet tools are mainly suitable for semi-finishing and finishing steel and cast iron parts with a hardness below HRC45. For difficult-to-machine materials above HRC45 (such as high-hardness cast iron rolls, high-chromium Alloy and other materials) it is better to choose cubic boron nitride tools or ceramic tools.

What can moresuperhard do for your procession of cermet cutting tools?

Moresuperhard is a superhard abrasives manufacturer from China.

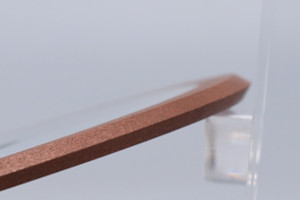

Moresuperhard provide double-sided diamond grinding disc to grind cermet standard inserts.

Diamond fluting wheel for cermet reamers,cermet end mills and cermet drill bits processing .

Resin bond diamond fluting wheel

Metal bond diamond grinding wheel for cnc grinder

More grinding wheel and grinding services ,please contact us freely.

PCD tools need to be ground because after long-term use, the surface of the tool will accumulate cutting slag, wear and edge failure, resulting in a decrease in cutting performance. Grinding can restore the sharpness and geometry of the tool, extend its service life, and improve processing efficiency and quality.

Alumina ceramic has high hardness (HV1900~2100) and high brittleness (flexural strength 240~260MPa). It is a typical hard and brittle material that is difficult to machine. Its grinding processing cost is high, the efficiency is low, and the surface and subsurface after grinding Crack groups appear in the area, affecting the stability of the workpiece.Moresuperhard have rich experience in grinding ceramic materials and we can recommand suitable grinding wheels for you.Moresuperhard have development different formulations grinding wheel for different ceramics materials.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088