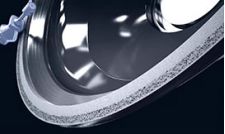

Vitrified bond diamond grinding wheel for PDC cutter

.jpg)

Introduction:

.jpg)

.jpg)

Advantage:

1. Ceramic binder is ceramic or vitreous, the binder is rigid, high temperature resistance, corrosion resistance, high stiffness to weight ratio, low density and strong chemical inertia.

2. Ceramic grinding wheel is conducive to the improvement of grinding performance, through reasonable proportion and production control, will not produce deformation, so that it is increasingly widely used in science and industry

3. The ceramic grinding wheel can adjust the hardness and porosity, which is beneficial to the improvement of grinding performance

4. High grinding efficiency, good machining accuracy.

.jpg)

Characteristic:

High hardness and wear resistance. The hardness of the polycrystalline diamond layer is generally in HV7000 ~ 9000, and the direction is consistent, which is 2 ~ 4 times of the hardness of the grinding wheel abrasive. With its high durability of grinding wheel, its volume wear ratio up to 1/13 million. Quality wear ratio up to 1/300,000, thus reducing production costs.

It has high bending strength. The bending strength of diamond is 210~490MPa, and the composite layer of PDC blade is supported by a thick hard alloy with higher bending strength, and its composite bending strength is up to 1500 MPa, so there is no breakage or fracture in the process of cutting.

The cutting force and cutting temperature are lower. The diamond composite sheet has a high thermal conductivity, 1.5 ~ 9 times of the hard alloy, 2 ~ 6 times of the copper, so that the temperature of the cutting area quickly spread out.

<< Prev Article:Vitrified bond CBN wheel for grinding cam shaft of Motorcycle

<< Next Article:Method of external grinding

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220