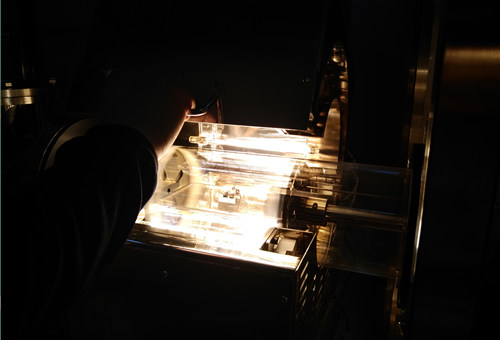

MORESUPERHARD can cut 8-10mm thickness PCD/MCD/CVD solid blanks, also can cut diamond slice at 0.2MM thickness...

MORESUPERHARD supply high frequency conduction brazing machine & vacuum brazing furane for your different req...

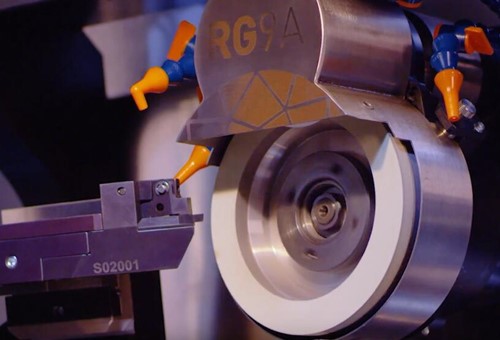

MORESUPERHAD can supply quality PCD grinding wheel at very long life as well as fast cutting. We only choose t...

MORESUPERHARD can provide oil stone, dressing wheel for dressing superabrasive diamond and CBN grinding wheels...

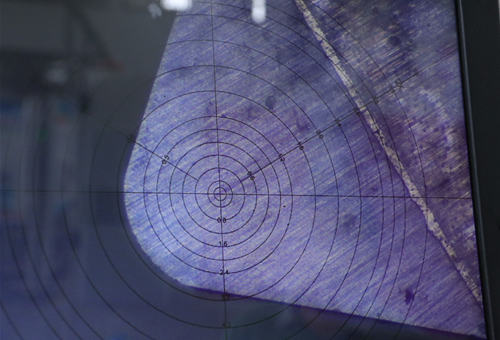

Customize special diamond grinding wheels for your PCD/PCBN/CVD/MCD/ND tools manufacturing and resharpening line. Processing the PCD/PCBN/CVD/MCD/ND materials with lapping, polishing, grooving, hold making, cutting. Resharpening, re-tipping your the PCD/PCBN/CVD/MCD/ND tools Supply the complete plant of cutting, brazing, grinding machine and various kinds of accessories like, brazing flux, solder, grinding wheels, dressing tools and PCD/PCBN/CVD/MCD/ND blanks for your cutting tools plant turnkey project including the installation and training of manpower by professional PCD grinding master who can use English face to face or online. Supply high quality CVD windows materials, ND tools for your any high-end industry application not only in cutting tools.

Welcome To Our Website. Any questions about PCD cutting, brazing and grinding, Call Us:+86 17700605088 or send us email (pcd@moresuperhard.com)

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088