Working process of vacuum furnace

Use a flux with a melting point lower than the connected workpieces, place it in a high vacuum chamber, and use infrared radiation to heat the workpiece and flux till temperature over the melting point of the flux. So that the flux becomes liquid with sufficient fluidity. Because of the capillary action, the flux will infiltrate over the surface between workpieces and joint the two workpieces after cooling down.

Advantages of vacuum furnace

※Easy to operate

※Do not require experience

※Lower the impact from manpower

※Quality remains stable

※Suit for PCD, MCD, CVD, Ceramic, CBN…materials

※Uniformly heated

※Avoid damages from pollution

※Clean and neat workpieces

※Automation

Features of vacuum furnace

High-quality brazed joins

Less distortion during brazing process will result in less the weariness of the cutter blade and cost down. Our sensors detect the presence of the abnormal condition and power failure. All the information from the sensors will be sent and integrated into the information system

Time saving

The whole process time for a finished working piece only takes about 30 min.

Easy-to-use operation

Automated process with simplified interface served with push button operation only.

Multi-functions

MoreSuperhard Vacuum Brazing Furnace can be used for wide range of tooling materials and it will reduce the deformation of the finished products. Tool materials can be placed in vertical, horizontal or oblique angle during the brazing process

Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

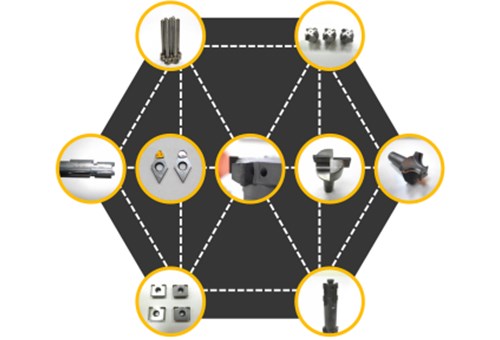

Applications

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

The finer the grinding wheel particle size, the smaller the cutting edge chipping, and the lower the grinding efficiency. For this reason, the PCD cutting tool sharpening process can be divided into three processing stages: coarse, fine, and fine according to the accuracy of the cutting edge of the tool, its purpose (see Table 1) or its failure degree (see Table 2). Formulating a reasonable sharpening process according to specific conditions can greatly improve processing efficiency.

MORESUPERHARD can not only provide you with efficient double surface fine grinding solutions, but also provide you with dressing solutions matching your double side grinding machine !

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088