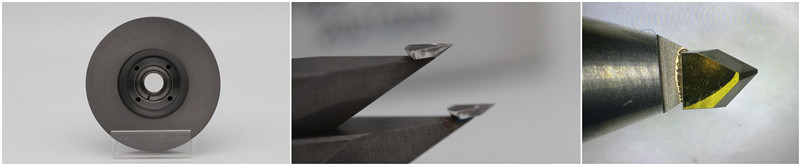

MORESUPERHARD provide private custom PCD cutting, brazing and grinding, regrinding solutions and services at first class. We also help resharpening and rebrazed the PCD machine tools at very good price. Surely, the effective PCD grinding wheels and grinding machines are our powerful core products which can match the EWAG, Coborn, MYTECH, Farman and any other PCD grinding machine perfectly because we can make different series grinding wheel for PCD with different grain sizes, area sizes, lengths, thicknesses, shapes, combined conditions with carbide substrate, as well as PCBN,CBN, CVD, MCD, ND, these superhard precision tools.

Experience is the best teacher. MORESUPERHARD was born with many years of experience in tool grinding, and its original intention was to help customers solve the problem of super-hard tool grinding.

2014:MORESUPERHARD founded.

2015: Established PCD division for solving super-hard cutting tools processing problems and established R&D center at the same time.

2017: Established grinding data collection and analysis center .The R&D center of MCD tool grinding was officially invested.

2020: Moresuperhard sucessfully producted 1mm ultra-narrow ring width vitrified diamond grinding wheel.

(The "Ceramic Grinding Everything" project was launched. Since entering 2020, Moresuperhard has specially established a "Ceramic Grinding Everything" project team according to the market situation, which is specially used to integrate the needs of customers for grinding various materials, including tungsten carbide, ceramics, cermets, PCD, PCBN, MCD and CVD, etc)

2021: Moresuperhard sucessfully produced 1μm ultra-fine-grained vitrified diamond grinding wheel.

2022: To be continued.

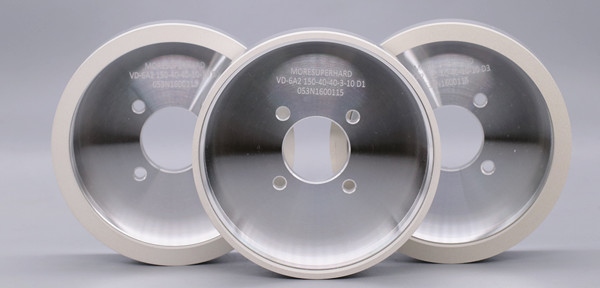

MORESUPERHARD independent research and develop "533" and "053" series vitrified diamond grinding wheel to meet the needs of customers for ultra-small size PCD, PCBN tools grinding.

"533" is ultra-precision grinding wheel with particle size of 3μm

"053" is ultra-precision grinding wheel with particle size of 1μm

Moresuperhard first developed fine-grained grinding wheels for high precise PCD tools process

Because traditional tools cannot meet the high efficiency and high precision requirements of high-precision industries, PCD materials enter various industries as the world's hardest tool materials. However, while the work efficiency is improved, a problem is also exposed - the machining accuracy of PCD tools cannot meet the requirements. After many measurements and studies, it was found that the occurrence of this situation was caused by the excessive collapse of the tool material itself, and the main reason for this problem was that the quality of domestic fine-grained grinding wheels was not as good as foreign ones. In order to meet the needs of more high-end customers, Moao began to focus on the research and development of fine-grained grinding wheels. At present, it has successfully solved the problems of difficult PCD material processing, low efficiency, short life and unsatisfactory precision for customers.

Moresuperhard further increased the CBN tool grinding production line

In the process of solving different problems for customers, we found that affected by the material properties, CBN tools have more advantages than PCD tools in the processing of some iron arrowhead metals. moresuperhard further increased the CBN tool grinding production line. Up to now, we have developed two different bond diamond grinding wheels, ceramic and resin, which can meet the processing needs of multiple CBN tools according to the grinding processing conditions of different customers.

Moresuperhard now specializes in the grinding wheels for processing single crystal tools

In recent years, with the rapid development of infrared, medical, and optical industries, single crystal tools have rapidly entered aerospace, mechanical weapon manufacturing and other industries. Even watches and jewelry that can be seen everywhere have begun to use single crystal tools for processing. According to customer processing equipment, industry precision requirements, and manufacturing capabilities, moresuperhard now specializes in the development of ceramic/metal bond grinding wheels, which are respectively applied to rough and fine grinding of single crystal tools, and have received many good feedbacks.

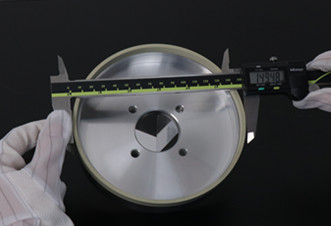

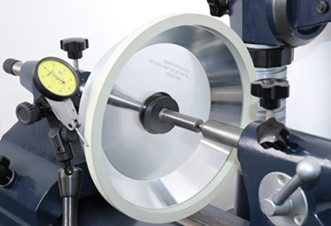

MORESUPERHRAD is engaged in quality control and outstanding service. All products and raw materials must pass quality inspection and will be shipped to customers.

♦ Strictly quality control for every-batch raw material (harness, crystal shape)

♦ Special high sharpness diamond for vitrified bond products

♦ Scientific production technology for excellent form and location tolerance

♦ Personal tailor of recipe, bonding agent and diamond concentration.

♦ Customized wheels formula to achieve perfect grinding

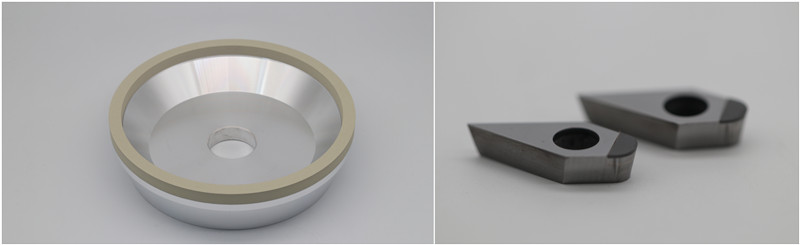

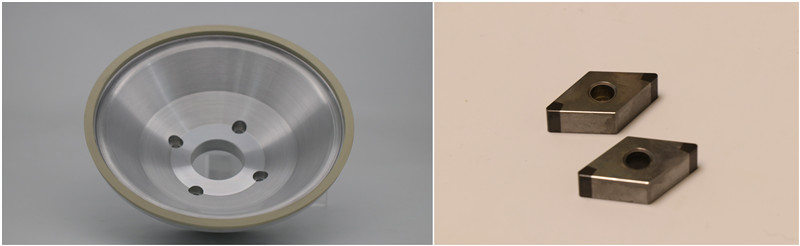

1. Vitrified bond, Resin bond, Metal bond diamond grinding wheels for PCD tools, PCBN tools, MCD tools, CVD tools, ND tools

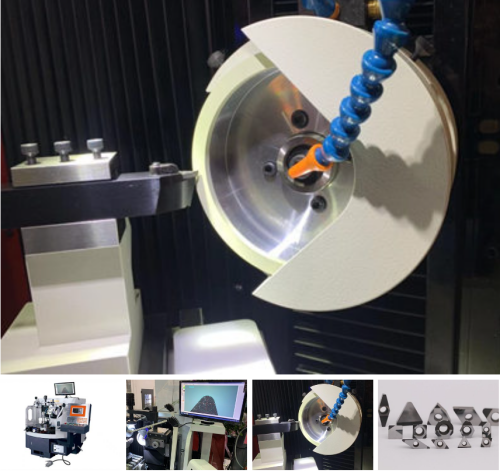

- 6A2 cup wheels for the EWAG RS series, Coborn RG series, MYTECH MT-188, MT-198 PCD grinding machines

- peripheral insert grinidng wheel for the Agathon, EWAG ewamatic, Waida, Wendt etc. famous inserts grinding machines.

- cylindrical diamond wheel for PCD reamers

- diamond wheel for single crystal tools

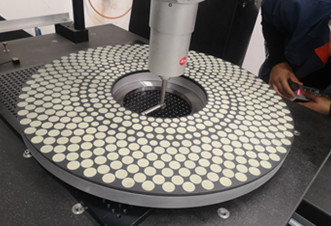

- double sided diamond disc for efficient grinding of tools in batches

- different bonded polishing wheels for the lapping suits different polishing machine.

2. Superhard Cutting tools blanks like PCD cutting tool blanks, PCBN cutting tool blanks, MCD blanks, CVD blanks.

3. Grinding machine for PCD,PCBN, CVD, MCD, ND tools especially MYTECH MT-188, MT-198 PCD grinding machine.

4. Dressing tools like WA dressing stone wheels for the Coborn RG9, RG9A, vitrified bond diamond dresssing wheels for the MYTECH MT-198 PCD grinding machine, which project is one high effeciency online dressing system research and develpment projfect between with MYTECH PCD grinding machine company and MORESUPERHARD.Surely we supply the dresssing sticks and dressing methods for the vitrified, resin and metal bond diamond grinding wheels for the PCD and PCBN cutting tools.

5. EDM and Laser cutting machine for PCD, PCBN materials.

6. Brazing machines and brazing materials, include the high induction frequecy brazing machine and materials and vacuum brazed machine and materials.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088