Brazing

Home / Brazing / Diamond Brazing Machines > high speed vacuum brazing machine

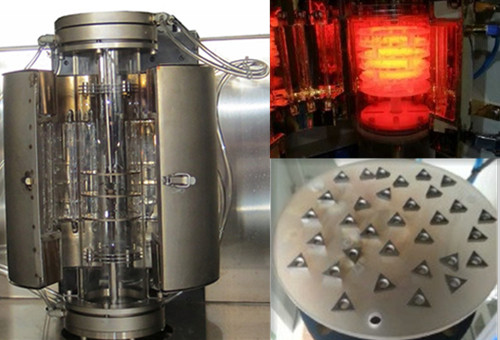

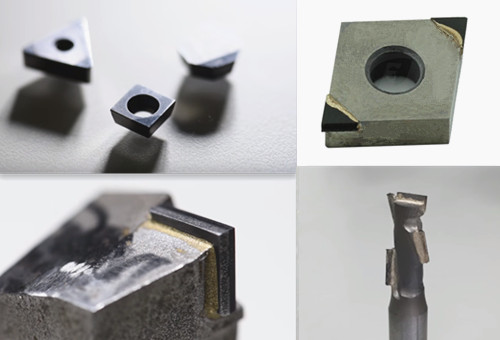

vacuum brazing machine is excellent for welding between superhard materials, tungsten carbide, ceramics and all kinds of diamond.The materials include ND (natural diamond),Synthetic Mono crystal diamond,CVD diamond,PCD/PCBN and cermet,etc.

vacuum brazing is often conducted in a vacuum chamber, this means that several joints can be made at once because the whole workpiece reaches the brazing temperature. vacuum brazing method realizes a shorter construction period, work environment improvement, enhancement of strength due to degassing and reduction of distortion due to wholly heating. The advantages include:

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088