Diamond Dressing Roller is a dressing tool for grinding wheels suitable for precision grinding machine

Characteristic:

1:High dressing accuracy

2:Difficult to change geometric dimensions

3:High dressing efficiency

4:Long services life, and low cost.

The working principle of the diamond rotary dresser

By installing the diamond rotary dresser on the dressing device of the grinder. Diamond rolls dress ordinary ceramic grinding wheels or CBN grinding wheels. The grinding wheels are trimmed and shaped before grinding the parts, thereby copying the contour, accuracy, and size of the diamond rollers to the surface of the processed parts through the grinding wheels.

Application of diamond rotary dresser

Gears, bearings, aerospace, weapons manufacturing, auto parts, air conditioning compressors, tools, measuring tools and other industries

Processing object

Superhard ceramic abrasives, superhard resin abrasives, ordinary ceramic abrasives, etc.

Characteristic

High dimensional accuracy, good shape retention and long life.

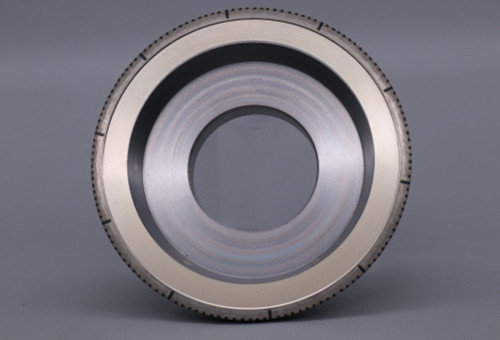

Main types of diamond rotary dresser

Forming diamond rollers:single-axis feed dressing

Single-axis rotary diamond dressers are used for grinding wheel shaping and are used in the series production of many different types of grinding wheels. Shorter dressing time, longer life, high productivity and consistent process conditions. A variety of general grinding wheels and some special super-hard grinding wheels can be dressed with this dressing method. CD dressing (continuous dressing) is commonly used for dressing grinding wheels used for machining hardened workpieces as well as high-temperature alloy fine profiles.

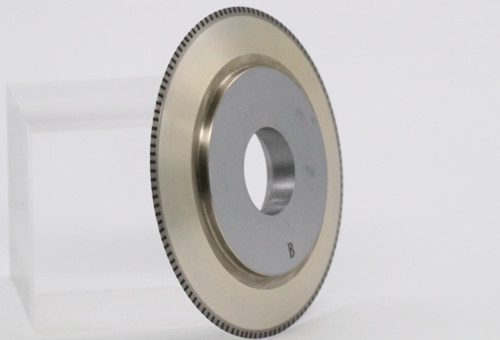

Diamond dressing Disk for flexible dressing

Dressing CNC dressing technology can be used in all areas of grinding production, especially small and medium-volume production and shaping applications. The flexibility of CNC control allows easy changes to the production process. Compared to single-axis insert trimming, CNC rotary trimmers have a lower cost per piece. Various types of grinding wheels can be dressed. CNC dressing discs with natural or CVD diamonds are used for dressing general grinding wheels. Self-sharpening rotary dressers are used to dress superhard grinding wheels. Precise optimization of dressing tools and spindle systems enables optimal runout tolerances and optimal dressing results for precision dressing applications.

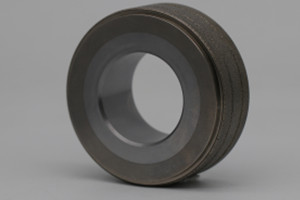

Diamond rotary dressers for Profile Grinding

Since gear grinding is one of the final operations in gear production, rotary diamond dressers must combine long life with correctly contoured grinding wheels to produce high-precision geometries and the highest quality surface finish.

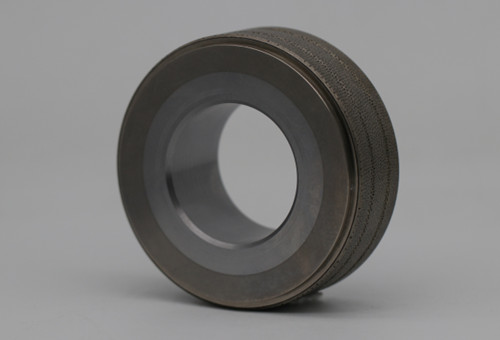

Dressers for Worm Gear Grinding

The production method of gear grinding is one of the most efficient processes for long-term production runs. Due to its extremely powerful dressing process, long-life electroplated gear dressers are used for this process. Innovation and continuous development of gear dressing machine manufacturing processes guarantee process-optimized dressing solutions for all machine systems.

Adaptation machine Germany's Hofler, the United States' Greintech-Pfaat, Germany's Kapniers, Switzerland's Klingenberg, Switzerland's Reishauer, Italy's Macanodo and Putansley gear grinding machines.

Moresuperhard provide precision diamond rotary dresser for various applications.Moresuperhard provide customized diamond rotary dresser according to your drawings.Moresuperhard also provide diamond rotary dresser design sevices for your grinding wheel.

Welcome your inquire!

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Polyetheretherketone PEEK has excellent comprehensive properties and can replace traditional materials such as metals and ceramics in many special fields. Moresuperhard has developed targeted grinding wheel formulas for the grinding of special engineering plastics such as PEEK, mainly electroplated grinding wheels, divided into rough grinding and fine grinding.

Diamond peripheral grinding wheels are used for peripheral grinding of PCD, CBN, carbide, ceramic, cermet and other indexable blades, flat blades, milling cutters, cutting blades, brazing blades, and machine clamp blades. At present, Moresuperhard peripheral grinding wheels have been successfully equipped with domestic and foreign mid-to-high-end peripheral grinding machines such as Hypertherm, Tiantong, Weize, WAIDA, EWAG, AGATHON, and WENDT, and have received unanimous praise from customers.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088