Agathon with a boutique pedigree

Switzerland is a country that produces high-quality goods, and it is also a place rich in centuries-old shops. The Swiss AGATHON company is one of them. Since 1918, the Swiss AGATHON company has made great achievements in the production of machine tools and standard components. success.

The successful of Agathon

In the market, the equipment of AGATHON more than 20 years ago is now a third-hand or even a fourth-hand machine tool, and there are still customers buying it, which is enough to show the stability and high rigidity of AGATHON machine tools. Agathon has made great efforts in product performance development and software. A lot of manpower and material resources have been continuously invested in system upgrades. Although these unremitting investments will not be immediately effective, some of them will not be able to produce economic benefits immediately, but what if there is no continuous research and development? The emphasis on research and development is to ensure that Agathon products are leading Cornerstone.

Advantages of AGATHON tool grinder

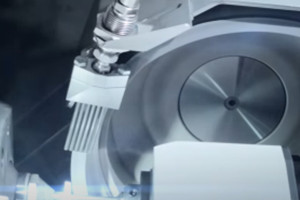

Agathon Leo Peri, a high-precision four-axis grinding center for pure peripheral grinding of indexable inserts, is suitable for machining inserts of all materials including cermet, CBN and PCD. This grinding machine occupies a small space , it not only inherits the advantages of AGATHON's well-received 250 series products, but also injects the latest research and development achievements, meets European CE certification safety standards, has small footprint but strong machine tool rigidity, ultra-short processing cycle, high efficiency and high precision The grinding wheel can be dressed online, and the automatic feeding system with a maximum of 6 trays has unparalleled stability.

what agaton's grinder can do?

Agathon's professional grinding machines can automatically process CNC inserts in a variety of materials, including carbide, ceramic, cermet, CBN and PCD. The high-performance machine tool realizes the automatic processing of various drilling tools, turning tools and milling inserts, as well as complex special-shaped inserts

Moresuperhard peripheral diamond grinding wheel suit agathon tools grinder

peripheral vitrified diamond grinding wheel

Grinding PCD, PCBN inserts. Preferred vitrified diamond grinding wheel for grinding PCD

Resin bond peripheral diamond grinding wheel for carbide indexable inserts grinding

Resin diamond wheels are used for grinding carbide inserts and ceramic inserts.

- Optimised strength and increased brittleness

- Good stock removal rate and low cutting-edge chipping

- Suitable for tungsten carbide, cermet and ceramic materials

- Reduced grinding forces during machining

if you need ,please contact us freely.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088