A natural diamond requires carbon atoms to be born at a depth of 150-200 kilometers underground and undergo hundreds of millions of years of high temperature and pressure. To appear in front of people, it must continue to be brought to the surface of the earth by geological movements over time. , it can be said to be very scarce. So by simulating the crystallization conditions and growth environment of natural diamonds, people used scientific methods to synthesize artificial diamonds that also have excellent properties such as super hardness, wear resistance, and corrosion resistance, shortening the synthesis time of diamonds to more than ten days or even a few days. Synthetic diamonds are divided into single crystals and polycrystals. They each have unique crystal structures and characteristics, making them different in applications.

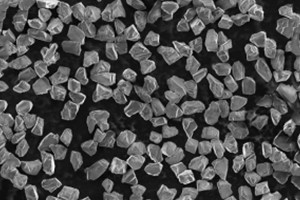

Single crystal diamond is a crystal bound by covalent bonds with saturation and directionality. It is the most common type of diamond crystal. The particles inside the crystal are regularly and synchronically arranged in three-dimensional space, with few defects. , without grain boundary restrictions, so it has outstanding advantages in thermal conductivity, hardness, light transmittance and electrical properties.

Applications of single crystal diamond

1.Thermal Conductive Applications of Single Crystal Diamond

The thermal conductivity of diamond basically comes from the propagation of carbon atom vibrations (that is, phonons). Impurity elements, dislocations, cracks and other crystal defects in diamond, residual metal catalysts, lattice orientation and other factors will collide with phonons. It scatters, thereby limiting the mean free path of phonons and reducing thermal conductivity. Single crystal diamond has a highly ordered lattice structure, which makes it almost unaffected by grain boundary scattering. Therefore, it has a thermal conductivity of up to 2200 W/(m·K). At the same time, diamond has stable chemical properties and high insulation. Based on these excellent properties, single crystal diamond is expected to be widely used in many fields such as semiconductor substrates.

2.Optical applications of single crystal diamond

High-quality single crystal diamond prepared by the CVD method can be completely colorless and transparent, with almost no impurities. Its highly ordered crystal structure also prevents light from being interfered by structural irregularities when propagating in the crystal, thus showing Produce more excellent optical performance. It has the widest transmission spectrum, from ultraviolet 225nm to infrared 25μm (except wavelength 1.8μm-2.5μm), and to the microwave range, single crystal diamond has excellent transmittance, with a theoretical transmittance as high as 71.6 %, microlenses (lenses, prisms, etc. in optical instruments) and infrared windows made of single crystal CVD diamond have excellent performance and are currently used in the aerospace field. In addition, single crystal diamond is a crystal Raman material with excellent performance, which allows Raman laser to achieve higher gain, higher power density and variable wavelength, providing new opportunities for the development of high-power lasers.

3.Single crystal diamond cutting applications

The microhardness of single crystal diamond tools is as high as 10000HV, so it has good wear resistance. Since the cutting edge of single crystal diamond can achieve atomic level straightness and sharpness, the perfect cutting edge can be copied directly onto the workpiece during cutting to produce a mirror surface with extremely smooth finish, ensuring extremely high dimensional accuracy. , and can maintain the tool life and stable performance under high-speed cutting and heavy load. It is suitable for ultra-thin cutting and ultra-precision machining. When processing non-ferrous metals, the surface roughness can reach Rz0.1~0.05μm, and the workpiece is processed. The shape accuracy is controlled below 50nm. At the same time, due to its low friction coefficient and small deformation during processing, the cutting force can be reduced.

4.Grinding and polishing applications of single crystal diamond

Single crystal diamond has good dispersion and higher utilization rate of sharp corners. Therefore, when it is prepared into a grinding fluid, the concentration is much lower than that of polycrystalline diamond, and its cost performance is relatively high. It is more suitable for polishing ceramics with less demanding requirements.

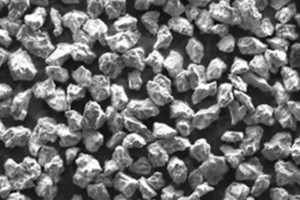

polycrystalline diamond

The structure of polycrystalline diamond is composed of many tiny nanometer-sized particles bonded through unsaturated bonds, which is very similar to natural black diamond (natural polycrystalline diamond with black or dark gray as the main color). Compared with single crystal diamond, polycrystalline diamond grains are arranged in a disordered manner, have good toughness, have a larger surface area, and will not suffer large-scale breakage when they withstand higher pressure. Currently, they mainly have the following application directions:

1.Application of polycrystalline diamond in semiconductor field

As semiconductor materials, the application directions of diamond polycrystalline and single crystal materials are quite different. The optical and electrical properties of polycrystalline diamond are not as good as those of single crystal diamond. The application of optical grade and electronic grade polycrystalline diamond films is relatively demanding. The preparation requires ideal deposition rate and extremely low or controllable defect density. However, in In terms of thermal conductivity, polycrystalline diamond still has a thermal conductivity close to 2000 W/(m·K). Therefore, polycrystalline diamond film is generally used as a heat sink for heat dissipation of semiconductor power devices. Compared with single crystal diamond, the technical level of its precipitation is also easier to achieve, and the advantage of preparation cost is also more obvious.

2.Application of polycrystalline diamond in the field of grinding and polishing

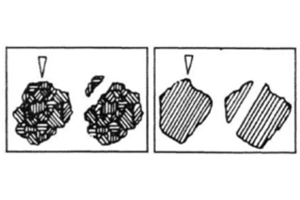

Since polycrystalline diamond grains are arranged in a disorderly manner, the micro-fractures produced when subjected to high pressure can be limited to a small range of microcrystals, without large cleavage plane fractures, and have good self-sharpening properties, so they are allowed to be Use higher unit pressure when grinding and polishing. During the grinding and polishing process, as the microcrystalline particles fall off, the polycrystalline diamond abrasive will continuously expose more equally rough and sharp crystallites, which means that regardless of the direction of the workpiece, it has many cutting edges, not only the material The removal rate is high, and the surface of the sample is polished more gently, which can avoid scratches on the surface of the workpiece. It is especially suitable for processing substrates such as sapphire and silicon carbide, and for grinding workpieces whose surfaces are made of materials with different hardnesses.

When subjected to pressure, the cleavage planes of polycrystalline (left) and single crystal (right) diamond break.

3.Application of polycrystalline diamond in the field of cutting tools

Compared with large single crystals of diamond, the disordered crystal structure of polycrystalline diamond gives it more impact resistance and is less likely to crack during cutting. Therefore, there are fewer restrictions in application and the application range is wider. At the same time, its affinity with non-metallic and non-ferrous metal materials is extremely low, and it is not easy to cause edge sticking during use.

Moresuperhard single-crystal diamond heat sinks offer ultra-high thermal conductivity (>2000 W/m·K), excellent electrical insulation, and a lightweight design, making them ideal for 5G, high-performance computing, RF power devices, semiconductor lasers, and aerospace applications.

Discover the key to optimizing single-crystal diamond tool performance with the right crystal face selection. Learn about (100) and (110) faces, their applications in precision machining, metal cutting, and semiconductor processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088