Austempered Ductile Iron (ADI) was Austempered nodular cast iron with austenite and Bainite matrix. Combining high strength bainite and spherical graphite structure. ADI has excellent comprehensive properties of high strength, wear resistance, noise absorption and vibration reduction, good notch sensitivity, high impact toughness and fatigue strength, while retaining the benefits of the original casting process, which can be made into various shape. Compared with cast steel, cast aluminum and other materials, it has the best economic performance.

|

Grade |

Tensile Strength

(MPa) |

Yield Strength

(MPa) |

Elongation

(%) |

Percussive Power

(J) |

Hardness

(HRC) |

|

1 |

900 |

650 |

9 |

100 |

34 |

|

2 |

1050 |

750 |

7 |

80 |

39 |

|

3 |

1200 |

850 |

4 |

60 |

47 |

|

4 |

1400 |

1100 |

2 |

35 |

52 |

|

5 |

1600 |

1300 |

1 |

20 |

56 |

|

US Standard – ASTM A897 / A897M-2015 |

|||||

After entering the 21st century, the application of ADI in automobile, construction machinery, shipbuilding heavy industry, agricultural machinery, metallurgical mining, wind power, high-speed railway accessories and other industries has developed rapidly. Such as light, medium, heavy trucks, crankshaft, camshaft, the gearbox output shaft, gear, suspension control arm, engine mounts, towing hook, suspension spring, ship’s engine cylinder liner, etc.

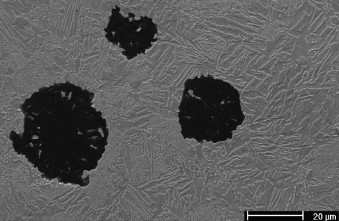

Similar to ordinary ductile iron, in ADI machining process, the strength of ferroalloy matrix and nodular graphite is completely different, which is equivalent to intermittent cutting, the tool vibrates greatly, and it is easy to cause the broken edge.

At the same time, considering the phase diagram and process of isothermal quenching heat treatment, ADI increased austenite formation elements such as nickel (Ni 0.73wt%) and copper (Cu 0.87wt%) in the composition, as well as molybdenum elements that play the role of strengthening and oxidation resistance, and the chip adhesion tools was serious, which increased the tool’s rapid wear.

The cutting speed is increased from 50m/min to 200m/min. The deformation and hardening of chip play a leading role. The hardness of chip and the main cutting force are increased. As the cutting speed continues to increase, the chip gradually changes from banded to serrated shape, the chip breaking effect gradually highlights, and the cutting force gradually stabilizes. When the cutting speed exceeded 400m/min, the increase of cutting deformation and cutting temperature induced martensitic transformation of the residual austenite in ADI microstructure, and the increase of chip hardness accelerated the acceleration of PCBN blade. Continue to improve the cutting speed, chip under high temperature tissue recovery and oxidation, blade wear intensified.

For the above problems in the processing of isothermal quenching ductile iron, as far as we know that all tool enterprises are lack of effective solutions. Generally speaking, considering the discontinuous cutting edge, it is preferred to use PCBN material with medium CBN content (65%, 70%, 75% at most), and it is better to use metal binder (titanium alloy or Al/Ni/Co). At the same time, appropriate coating is also an effective means to improve the ADI processing efficiency of PCBN.

<< :The world's first launch- COBORN PG6 Diamond tools Grinding machine on 2020.9.9-9.11 SHENZHEN CITY

Diamond wafers have great potential in high-end fields such as quantum computing, microwave power devices, and semiconductor lasers due to their ultra-high hardness, excellent thermal conductivity, and wide bandgap properties.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088