Performance of PCBN tool material

According to its manufacturing process, PCBN is divided into CBN directly combined into a sintered block through high temperature and high pressure, or sintered at high temperature and high pressure with a binder such as metal or ceramics; according to the final composite method, there are separate CBN sintered blocks and CBN / PCBN composite sintered hard alloy composite sheet. This article will focus on the cutting performance of PCBN composite chip tools.

1. High hardness and wear resistance

The crystal structure of CBN is similar to that of diamond, with the same chemical bond types and similar lattice constants, so it has similar hardness and strength to diamond. The microhardness of CBN powder is HV8000~9000, and the hardness of the sintered PCBN is generally HV3000~5000.

2.High thermal stability

The heat resistance of CBN can reach 1400~1500℃, and the hardness of PCBN at 800℃ is higher than the normal temperature hardness of ceramics and cemented carbide.

3. Excellent chemical stability

CBN is extremely chemically inert. It does not chemically react with iron-based materials at 1200-1300°C, and only reacts with carbon at 2000°C; it is stable to acids and alkalis in neutral and reducing gases. Its bonding and diffusion effect on various materials is much smaller than that of cemented carbide

4. Good thermal conductivity

Among all kinds of tool materials, the thermal conductivity of CBN is second only to diamond, which is much higher than that of cemented carbide, and as the temperature rises, the thermal conductivity of PCBN increases.

5. Low friction coefficient

The coefficient of friction between CBN and different materials is 0.1-0.3, and that of cemented carbide is 0.4-0.6. As the cutting speed increases, the friction coefficient decreases.

Cutting characteristics of PCBN tools

PCBN tool materials have the above-mentioned special properties, so under different cutting conditions, they show special laws different from other materials.

1. Cutting high hardness and hardened steel with long tool life

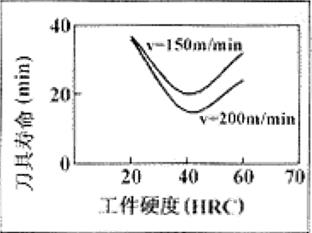

When PCBN tools cut hardened steel, as the hardness of the processed material increases, the tool life is not monotonously decreased, but the tool life is the lowest at HRC40 (as shown in Figure 1), Figure 1VB=0.2mm; ap=0.5mm ; F=0.1mm/r, workpiece material: 35CrMo. When the hardness of the workpiece material is higher than this hardness, the tool life will increase instead. This is mainly due to the low hardness loss of PCBN material at high temperature, and when the workpiece material has a high hardness, the metal in the cutting area will be softened due to the cutting heat, which makes the cutting process easier. The characteristic of PCBN is very suitable for processing high-hardness materials. Turning instead of grinding can obtain the surface quality that can only be obtained by grinding.

Figure 1 The relationship between tool life and the hardness of the processed material

2. Cutting tool life of normalized steel is low

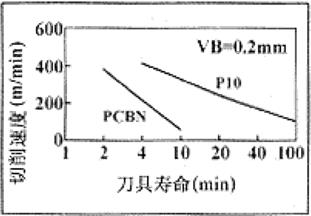

When cutting normalized materials, the life of PCBN tools is lower than that of cemented carbide tools (as shown in Figure 2), the cutting amount: f=0.1mm/r; ap=0.5mm. And the tool life is lower than when cutting hardened steel. It can be seen that PCBN tools are not suitable for processing normalized materials.

Figure 2 The relationship between cutting speed and tool life when cutting normalized steel

3. The tool life curve of cutting gray cast iron is bent

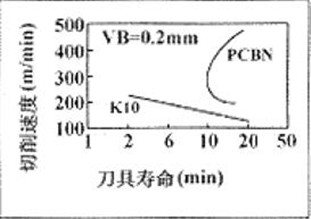

The relationship between the tool life and cutting speed of cutting gray cast iron PCBN does not conform to Taylor's formula. The flank wear VB and rake face crescent wear depth KT both show the same law (as shown in Figure 3). Figure 3 Cutting Dosage: f=0.1mm/r, ap=0.5mm.

Figure 3 The relationship between tool life and cutting speed when cutting gray cast iron

4. Tool life is higher than diamond tool when cutting wear-resistant brass

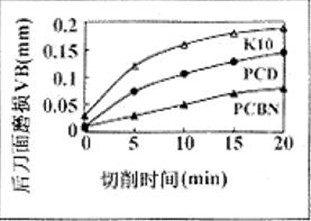

When cutting non-ferrous metals, sintered diamond (PCD) is usually the best tool material, but when cutting wear-resistant brass, PCBN tool life is higher than that of sintered diamond and cemented carbide tools (as shown in Figure 4). Figure 4 Cutting consumption: v=200m/min; f=0.2mm/r, ap=1.0mm.

Figure 4 Tool wear curve when cutting brass

5.PCBN tool life is high at high speed

As shown in Figure 5, cutting parameters: f=0.05mm/r, ap=0.05mm; workpiece material: HPM31HRC57; ball end mill R5 down milling Figure 5 shows the relationship between the tool flank wear and the cutting distance when PCBN tools cut hardened steel at different speeds. It can be seen from Figure 5: when the cutting speed exceeds a certain limit, the higher the cutting speed, the higher the tool wear speed On the contrary, it is reduced, that is, the life of PCBN tools at high speeds is higher than that at low speeds, so PCBN tools are suitable for high-speed cutting of high-hardness materials.

.jpg)

Figure 5 PCBN tool life at different speeds

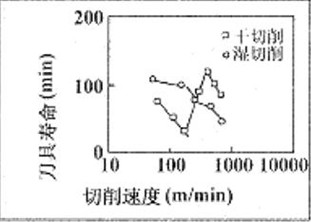

6. PCBN tool life is high under dry cutting conditions

As shown in Figure 6, the workpiece material is cast iron, which is a comparison of the tool life of PCBN tools under dry and wet cutting conditions. It can be seen from Figure 6 that in the case of dry cutting, the life of the PCBN tool is actually higher than that of the cutting fluid. The main reason is that the cutting temperature is high during dry cutting, and the high temperature hardness of PCBN is high, so the hardness loss is less, and the workpiece material The hardness loss is large at high temperature, and it is easier to cut after the hardness is reduced.

Figure 6 The relationship between PCBN tool life and cutting speed in dry and wet cutting

The surface quality of PCBN tools

PCBN tools not only have excellent cutting performance, but also can obtain surface quality that is difficult to obtain with other types of tools.

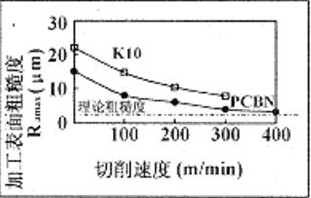

1.Lower surface roughness can be obtained

Different materials can be processed with PCBN tools to obtain lower surface roughness. Figure 7 shows the comparison of the surface roughness of PCBN tools and cemented carbide tools when processing cast iron. It can be seen from Figure 7 that the surface roughness of PCBN tools is much better than that of carbide tools, and with the increase of cutting speed, it is getting closer and closer to the theoretical value of roughness. In addition, due to the high hardness and wear resistance of PCBN tools, a more consistent surface roughness can be obtained in a long time. Figure 7 Workpiece material: cast iron FC25; cutting amount: f=0.1mm/r; ap=0.3mm.

Figure 7 Processed surface roughness of PCBN tool

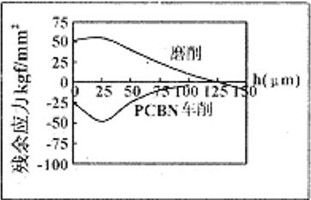

2. Good surface stress state can be obtained

As shown in Figure 8, the machined surface obtained by grinding usually produces tensile stress. When hardened steel is processed with PCBN tools, the surface structure of the workpiece usually has residual compressive stress, which can improve the fatigue strength and wear resistance of the part. Figure 8 Cutting conditions: workpiece material: GCr15 quenching; grinding: v=35m/s; vf=10mm/min; fr=0.008mm; turning: v=70m/min, f=0.07mm/r; ap=0.1mm .

Figure 8 Residual stress on the machined surface obtained by PCBN tool cutting

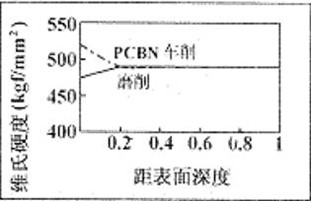

3.Changes in surface hardness of the machined surface

The comparison between the surface hardness of PCBN tool cutting hardened steel and the grinding is shown in Figure 9. It can be seen from Figure 9 that the surface hardness of the workpiece obtained by grinding has decreased, while the hardness of the machined surface obtained by PCBN tool processing has increased slightly, which improves the mechanical properties of the machined surface. Fig. 9 Workpiece material: SCM21, quenched HRC50; cutting amount: turning: v=300m/min; f=0.3mm/r; ap=1.0mm; grinding: vc=1450m/min; vw=80m/min; ap= 0.015mm. In addition, when the PCBN tool cuts hard materials, the cutting heat generated by the tool's good thermal conductivity is taken away by the chips, and the surface fiber structure of the workpiece surface does not change significantly. If the cutting amount is not selected properly, the surface is easy to produce burn.

Figure 9 Changes in surface hardness of PCBN tools

Conclusion

PCBN cutting tools have better cutting performance than other material cutting tools, especially suitable for the cutting of high-hardness hardened steel and wear-resistant materials. It has excellent cutting performance in high-speed cutting and dry cutting. It can be used under certain conditions. The machining surface quality is comparable to that of grinding; however, PCBN tool life has a special change rule, such as: low tool life when cutting medium-hardened hardened steel and normalized steel, bending of the tool life curve when cutting cast iron, etc. Understand and master these special laws, you can give full play to its superior cutting performance in use, and create huge economic benefits.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088