High aliumina ceramic workpieces

A ceramic manufacturing company mainly produces high-precision high-alumina ceramic parts, which are widely used in aerospace, electronics and medical equipment due to their excellent wear resistance and corrosion resistance. Recently, the company received a difficult order to process a high-alumina ceramic workpiece with a size of 110mm x 110mm x 3.2mm. It is required to grind 1mm on both the upper and lower surfaces and ensure that the surface finish after grinding is Ra≤2μm. This places extremely high demands on processing accuracy, grinding efficiency and surface quality.

Moresuperhard grinding solutions for grinding ceramic workpieces

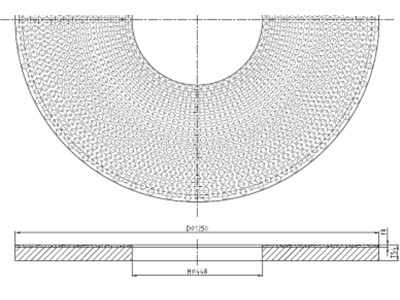

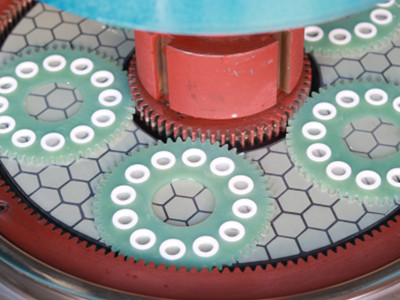

After a detailed demand analysis, according to the grinder used by the customer, a ceramic bond diamond double-end grinding disc with a diameter of D1250mm is required. Moresuperhard designed double-end grinding discs equipped with round diamond grinding blocks with a particle size of 170/230#, which are specially designed for grinding high alumina ceramics.

Characteristic of Moresuperhard doual face diamond grinding disc

High-precision grinding: Through the rational distribution of diamond grinding blocks and finely controlled particle size, the cutting force during the workpiece grinding process is ensured to be uniform, the surface stress and thermal damage of the workpiece are reduced, and the surface finish of Ra≤2μm is finally achieved.

Efficient material removal: Although the high-alumina ceramic material is hard and brittle, the diamond grinding disc can stably control the grinding amount while grinding efficiently. The material removal of 1mm on each side of the workpiece is completed smoothly within the specified time, which greatly improves production efficiency.

Grinding machine matching: In order to maximize the performance of the grinding disc, the grinding disc is precisely designed according to the double-end grinder used by the customer, so that the customer's grinder and our grinding disc fit perfectly, ensuring stability and consistency during the processing.

Customer feedback for Moresuperhard double end grinding disc

After using Moresuperhard ceramic bond diamond grinding discs, the company successfully completed the order. According to customer feedback, the grinding discs showed excellent grinding performance during the processing, which not only improved production efficiency, but also ensured that the surface quality of the products fully met the standards. Especially for difficult-to-process materials such as high-alumina ceramics, the ability to meet the expected requirements in such an efficient way has made customers highly recognize our products.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088