Polycrystalline diamond (PCD) tool material not only has high hardness, good wear resistance, and isotropy, electrical conductivity, weldability and economic advantages, so it has been widely used in the field of processing non-ferrous metals and non-metallic materials.

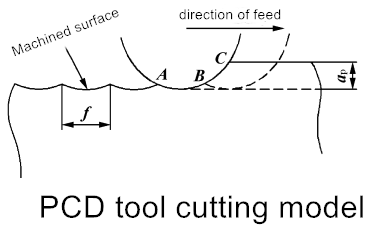

In the relative motion of the tool and the workpiece material, the ABC section of the cutting edge touches the workpiece, and the AB section of the cutting edge plays a direct role on the surface of the workpiece.

For the PCD tool, the workpiece processed by it is usually non-ferrous metal with large elastic-plastic, so the surface of the workpiece will produce elastic recovery and complete contact with the knife surface after extrusion by AB section edge Plastic deformation and elastic deformation occur under the action of normal force and friction force applied to the rear cutter face, and finally the rear cutter face is displaced to form the workpiece surface.

According to the analysis of the PCD cutting model, the machineed surface is formed by the interaction between the rebound of the workpiece material after extrusion by the edge and the tool back surface. For ordinary tools, this interaction increases the friction between the tool and the workpiece due to insufficient hardness, wear resistance and rear surface finish of the tool material, which ultimately accelerates tool wear and greatly reduces the quality of the processed surface.

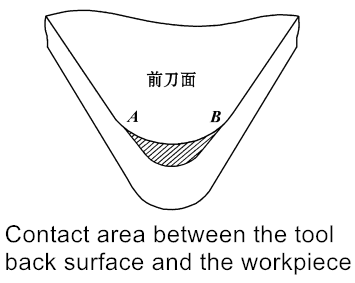

The PCD tool after the knife surface is generally quite smooth, and the PCD material has high hardness and wear resistance, so the PCD tool after the face of the workpiece surface plays an important role in ironing, especially in the cutting of non-ferrous metals, because the material is soft, elastoplastic, the ironing effect is more prominent, Therefore, the quality of PCD tool back surface grinding directly affects the surface quality of the workpiece. Improving the quality of PCD tool back surface grinding is very beneficial to improve the surface quality of the workpiece.

PCD tool after the knife face cutting surface ironing, the first PCD tool after the knife surface quality is good, high smoothness, so the workpiece surface after the ironing, the surface is smooth, but due to the existence of Si particles in silicon aluminum alloy, will inevitably lead to the processing of fine scratches on the workpiece surface.

The grinding quality of the PCD tool back surface has a direct impact on the surface quality of the workpiece. The higher the surface quality of the back surface is, the less scratches are left in the geometric reflection region of the tool on the processed surface, and the higher the quality of the processed surface is.

The hardness and wear resistance of PCD tool material is very high, and the tool life is long. Normally in the knife when cutting tool grinding surface grinding marks left by the little impact on the tool life, only when grinding the blade surface quality severely damaged after PCD cutting tools, such as a pit, spalling of PCD block or surface thermal damage after severe that knife surface produced a thick layer of softening, etc will make the life of the PCD cutting tool is reduced greatly.

<< :CBN grinding wheel process characteristics

<< :Analysis of surface roughness and edge wear of aluminum alloy processed by PCD tool

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088