Grinding characteristics of PCD and sharpening technology of PCD tools

Abstract: This paper introduces the manufacturing process of PCD cutting tools, analyzes the grinding characteristics of PCD materials and the requirements of PCD tool sharpening on the tooling, and focuses on the sharpening process and main points of PCD cutting tools.

Keywords: PCD, cutter, sharpening

.jpg)

.jpg)

1 Introduction

With the rapid development of modern science and technology, the variety of tools made of superhard materials such as polycrystalline diamond (PCD) and polycrystalline cubic boron nitride (PCBN) is becoming more and more abundant, and their performance has been continuously developed and improved. Blade abrasive particle size from tens of micrometers, several micrometers to nanometers; the content of diamond and cubic boron nitride is divided into low content, medium content and high content; the binder includes both metal, nonmetal and mixed materials; Millimeter level to micron level; the combination of PCD layer and hard alloy substrate has flat surface and corrugated surface; PCD layer has different characteristics such as high wear resistance, high toughness and high heat resistance. At present, the application range of PCD and PCBN tools is expanded to the automotive, aerospace, precision machinery, home appliances, wood, electronic and electrical industries, etc. Knife, razor, etc.

Although the development of PCD and PCBN tools is so fast, the difficulty of sharpening the tools due to their high hardness has always troubled most users, and the resharpening of the blades is mainly done by the original tool manufacturers. Not only are the prices of tools high, the lead time is long, but they also occupy the working capital of enterprises and institutions. Therefore, it is necessary to carefully study the grinding characteristics of PCD and the grinding technology of PCD tools.

2 PCD tool manufacturing process

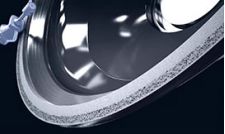

The production process of PCD cutting tools generally includes polishing, cutting, fixing, sharpening, and quality inspection. The diameter of PCD superhard material is usually 1/2, 1, 2, 3, 4 inches, and its surface is generally rough (Ra2 ~ 10μm). It cannot be used directly for making tools. ≤0.01μm); then laser cutting or wire-cut EDM is used to produce blades with certain geometric shapes and sizes; further mechanical and chemical treatment is performed on the blade and the substrate to be fixed, and then silver-based brazing is used to The blade is fixed on the substrate; finally, it is sharpened by a diamond wheel.

One of the keys to PCD cutting tool manufacturing technology is the grinding quality of the cutting edge. The lack of ideal sharpening technology and technology for high-quality cutting head materials will cause waste of resources. The use of a good sharpening technology will improve the quality of the tool and reduce the cost of the tool.

3 PCD material grinding characteristics

PCD is made of specially treated diamond and a small amount of binder under high temperature and high pressure. The randomly arranged diamond grains make PCD have uniform, extremely high hardness and wear resistance. PCD can be used for cutting tools, grinding wheel dressing, geological drilling, measuring probes, wire drawing tools, sand blasting tools, etc. However, PCD's high hardness and high wear resistance also lead to great difficulties in its processing.

Scholars at home and abroad have conducted a lot of research and tests on processing problems caused by the high hardness and high wear resistance of PCD materials, including electric discharge machining, ultrasonic machining, electrochemical machining, and laser machining, and have achieved certain results. . However, comprehensive analysis found that these processing technologies are currently suitable for rough machining of PCD materials. To obtain good PCD cutting edge quality, the most ideal machining method is still grinding or grinding with diamond wheels.

PCD grinding is mainly the result of a mixture of mechanical and thermochemical aspects. Mechanical action is the micro-breaking, abrasion, shedding or cleavage of diamond formed by the continuous impact of diamond grinding wheel abrasives on PCD materials; thermochemical action is the high temperature formed by diamond grinding wheel grinding PCD to oxidize or graphitize the diamond. As a result of the mixed effect, the PCD material was removed. Its grinding processing characteristics are mainly:

(1) Great grinding force

Diamond is the hardest substance in the known minerals. The friction and wear of paired metals and non-metallic materials is only 1/50 ~ 1/800 of cemented carbide. The hardness (HV) of PCD is 80 ~ 120KN / mm2. , Second only to single crystal diamond, much higher than cemented carbide. When using a diamond wheel to grind PCD, the initial cutting strength is very high, about 10 times that of cemented carbide (0.4MPa); the specific grinding energy can reach 1.2 × 104 to 1.4 × 105J / mm3; therefore the grinding force is much higher For grinding carbide.

(2) Grinding ratio is small

Because PCD has high hardness and abrasion resistance (relative wear resistance is 16 to 199 times that of cemented carbide), the grinding ratio of PCD is only 0.005 to 0.033, which is about 1/1000 to that of cemented carbide. 1/100000; grinding efficiency is only 0.4 ~ 4.8mm3 / min. Therefore, in order to ensure the cutting edge quality and removal amount of the cutting tool, the grinding time is very long and the machining efficiency is very low. In addition, when the hardness, content, and particle size of PCD are different, the grinding time varies greatly.

(3) Granularity has a great influence

PCD materials used for cutting tools are mainly divided into three categories according to particle size: coarse grain size (20-50 μm), medium grain size (about 10 μm) and fine grain size (-5 μm). The grinding force and grinding ratio differ by several to several times. ten times. Coarse-grained PCD has the highest grinding ratio and the most difficult grinding, and the sharpest edge sawtooth shape and the worst quality after grinding, but the strongest wear resistance; Fine-grained PCD has the lowest grinding ratio, which is easier to grind. The quality of the cutting edge is the best after grinding.

4 PCD cutting tool sharpening requirements for tooling

Based on the above-mentioned grinding characteristics of PCD, the requirements for sharpening equipment for grinding PCD with diamond wheels are much higher than for general tool grinding machines. There are:

(1) The machine tool has good process system rigidity

Due to the high hardness of the PCD material, the grinding machine must have a high resistance to deformation, especially the spindle system and the tool clamping system. The grinding force of PCD cutting tools during grinding is generally 100 ~ 500N. Therefore, the shaft diameter of the machine tool is large, and the axial rigidity and strength of the bearing are high.

(2) The machine tool has a short-range swing mechanism with adjustable stroke and speed.

The grinding ratio of PCD is extremely low. The grinding processing mechanism of PCD is mainly the result of a combination of mechanical effects such as micro-breaking, wear, shedding, cleavage, and oxidation and graphitization thermochemical effects formed by the continuous impact of diamond wheels on PCD materials. . Therefore, the use of a short-range swing mechanism is conducive to improving the grinding efficiency and improving the cutting edge quality. Generally, the swing distance is 0-50mm, and the swing speed is 20-60 times / minute.

(3) The tool holder of the machine tool has a high-precision turning function and an online detection device

Because PCD material is hard, brittle and wear-resistant, its tip is usually designed to be arc-shaped to help reduce the amplitude of the relative vibration of the tool and the workpiece. In order to realize the processing of the tool tip arc, the tool holder of the machine tool should have a high-precision turning function and an on-line detection device for the tool tip arc radius size and quality. In this way, positioning errors caused by multiple clamping can be avoided, and the processing efficiency can be doubled.

5 PCD, PCBN tool sharpening process

5.1 Selection of honing sharpening process

One of the purposes of cutting tool sharpening is to obtain a cost-effective cutting edge quality, and the key to good quality is the choice of the size of the grinding wheel. The finer the grinding wheel, the smaller the cutting edge chipping and the lower the grinding efficiency. To this end, the PCD cutting tool grinding process can be divided into three stages of rough, fine and fine according to the precision, use of the cutting edge (see Table 1) or the degree of failure (see Table 2). Formulating a reasonable sharpening process according to specific conditions can greatly improve processing efficiency.

Roughing does not have high requirements on the cutting edge. You can choose electric machining or grinding. Electrical processing is efficient, and it is suitable for machining complex tools, such as drills for printed circuit boards, forming milling cutters for cutting laminate flooring, etc. Coarse-grained grinding wheels can be selected during grinding, with large contact area during grinding and high grinding force (300 ~ 400N), which can quickly remove excess machining allowance; fine-grained wheels are used for fine machining, and small contact area during grinding , Low grinding force (100 ~ 200N), less heat generation during grinding, but low material removal rate. This stage is mainly to further improve the cutting edge quality by grinding and polishing. Finishing is in between.

5.2 Key points of honing sharpening process

(1) The spindle accuracy should be good. Generally, the runout of the grinding wheel end face should be ≤0.02mm. The bounce of the end surface of the grinding wheel is too large, and the grinding wheel intermittently impacts the cutting edge during grinding, which easily causes the cutting edge to collapse, and it is difficult to obtain a high-precision cutting edge;

(2) The grinding wheel should have good dynamic balance. The imbalance of the grinding wheel will cause the vibration of the machine tool, and then affect the cutting edge quality and machining accuracy of the machined tool;

(3) Diamond grinding wheels with ceramic bonding should be preferred. Because the ceramic bonding agent is prone to microcracking during the grinding process, the abrasive particles are renewed and sharpened, so that the grinding process is stable, which is conducive to improving the accuracy and efficiency of the processed surface; secondly, a resin bonding agent with higher heat resistance can be selected Diamond grinding wheel;

(4) Pay attention to the cutting edge of the grinding wheel in time, and the particle size of the cutting stone should be appropriate. When a PCD tool is machined with a diamond wheel, the wheel will become clogged, passivated, high temperature, and rapidly worn, resulting in reduced processing speed and chatter, noise, and burns. Generally, soft silicon carbide whetstones with a size of 1 to 2 finer than the grinding wheel used are used as cutting whetstones;

(5) Because diamond easily diffuses with iron-based alloys and accelerates wheel wear, it should be avoided to grind metal and PCD at the same time.

(6) The turning direction of the grinding wheel must be turned from the front face of the tool to the back face. From the force of the cutting edge of the PCD tool during grinding, it is known that when the grinding wheel rotates from the rake face to the flank face, the grinding force (the sum of the tangential and normal forces) acts on the cutting edge inward, that is, the tool is subjected to Compressive stress is not easy to collapse; otherwise, it is tensile stress, and the cutting edge is easy to collapse. If the sharpening must be reversed due to the structure of the tool, the resin bonded grinding wheel is better than the metal and ceramic bonded grinding wheels;

(7) In order to ensure the quality of the cutting edge and improve the grinding efficiency, the rake angle of the tool can be divided into a large rake angle and a small rake angle. The coarse-grained grinding wheel is used to grind the large back angle first. Due to the large grinding force of the contact surface, the grinding efficiency is high; then the fine-grained grinding wheel is used to sharpen the small back angle, and the edge width of the small back angle is controlled to about 0.1 to 0.3 mm , The quality of the small sharpening of the contact surface is good;

(8) As far as possible, complete the machining of the cutting edge of the tool in one clamping;

(9) PCD grinding coolant should be water-based grinding fluid. Because PCD material has high hardness and poor heat resistance, the cooling effect of water-based grinding fluid is better than that of oil-based grinding fluid, which can improve the processing efficiency and the quality of the cutting edge. In addition, during the grinding process, the cooling should be sufficient, and the flow should not be interrupted to avoid the large consumption of diamond (grinding wheel, tool) (oxidation, graphitization) and the cutting edge of the tool due to the small amount of grinding fluid or intermittent supply.

.jpg)

<< Prev Article: 150M PCD Tool Grinding Machine

<< Next Article:CNC tool grinder diamond grinding wheel automatic dressing and compensation method

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220