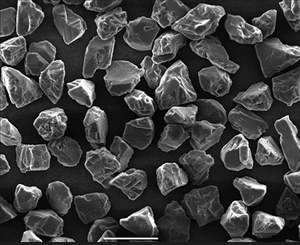

Grinding process of single abrasive grain

The grinding process of a single abrasive grain is roughly divided into three stages: Slip, scribing and cutting.

(2)Scribing stage: As the depth of squeezing of the abrasive particles increases, the pressure between the abrasive particles and the surface of the workpiece gradually increases, and the surface layer transitions from elastic deformation to plastic deformation. At this time, the squeeze friction is intense, and a lot of heat is generated. When the metal is heated to the critical point, the normal thermal stress exceeds the critical yield strength of the material, and the cutting edge begins to cut into the surface layer of the material. The slip causes the surface layer of the material to be pushed to the front and both sides of the abrasive grain, so that the abrasive grain scores groove marks on the surface of the workpiece, and the two sides of the groove mark are raised. The characteristics of this stage are: plastic flow and bulge on the surface of the material, because the cutting thickness of the abrasive grains does not reach the critical value of chip formation, and cannot form chips.

(3)Cutting stage: when the squeezing depth increases to the critical value, the cut layer slips along the shear plane obviously under the squeezing of the abrasive grains, and the formed chips flow out along the rake face. This is called the cutting stage.

<< Prev Article:Best grinding wheel or “YOUR”wheel

<< Next Article:Cylindrical grinder structure

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220