Grit size selection in PCD tools grinding

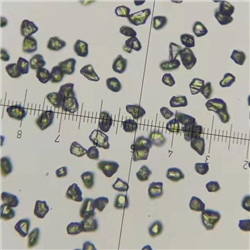

Grit size selection:

Grit size influences the grinding efficiency and grinding surface grade.

Holding force is not enough when grit size is too rough, and grain falls off. The working life of wheels goes down rapidly. If grit size is too fine, the grinding wheel is jammed easily, big quantity heat is generated, it burns the workpiece and makes grinding efficiency reduced very much. Thus, we need to choose the right grit size for specific grinding purpose. Rough grit for roughing, fine grit for finishing. This is an important rule in super-hard material grinding, especially for PCD & CBN tools grinding.

Usually, in PCD tools grinding, we choose 40 μm – 14 μm grain size for rough grinding, to get higher stock removal. And choose 10 μm – 3 μm grain size for fine grinding, to get better surface grade and cutting edge quality.

In addition, we should also consider the grit size of PCD tools, the performance and quality of grinder, and specific production requirement to choose the right grit size.

<< Prev Article:PCD tools for Graphite precision turning

<< Next Article:PCD forming tools power sytem (cylinder head)

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220