HOW TO POLISH GEM WITH RESIN BOND DIAMOND LAPPING WHEEL

HOW TO POLISH GEM WITH RESIN BOND DIAMOND LAPPING WHEEL

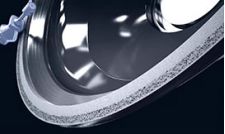

To Get The Best Results, It Is Recommend To First Cutting The Stone On A Cutting Disc Of 600 Or 1200 Mesh. Polishing Is Accomplished With A Constant Drip Of Water By Moving The Stone Across All The Area Of The Lap, To Obtain A Brilliant Flat Surface. It Is Important To Move The Stone Across The Entire Surface Of The Lap In Order To Maintain A Smooth And Flat Polishing Surface.

The Polishing Powder Is Impregnated Into The Resin Bond Lap Eliminating The Need For Any Additional Agents. All That Is Added Is Water. This Long Lasting Lap With A Polishing Layer Of 6mm, Only Requires Dressing From Time To Time. Recommended Operating Speed Is Up To 1500 RPM. When A Light Dressing Is Needed, A Fine Carborundum Bar Can Be Used To Remove Any Ripples And To Restore A Perfect Flat Surface. Plenty Of Water Is Required While Dressing.

Resin Diamond Grinding Laps Is Mainly Used For Glass Polishing And Crystal Polishing, Like Gemstone, Quartz Glass, And Agate Etc. Resin Bond Diamond Grinding Discs Are Widely Used For Fine Face Grinding In Various Industries.

<< Prev Article:THE PRODUCTION TECHNOLOGY OF VITRIFIED BOND DIAMOND GRINDING WHEEL

<< Next Article:Development Prospect Of Abrasive Market

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220