Material classification of precision glass tubes

Precision glass tubes can be divided according to materials: high silicon borosilicate glass tubes, quartz glass tubes, neutral borosilicate glass tubes, crystal glass tubes, ordinary glass tubes, and special glass tubes.

High silicon borosilicate glass tube

Compared with ordinary glass, high-silicon borosilicate glass tubes have no toxic side effects. Its mechanical properties, thermal stability, water resistance, alkali resistance, acid resistance and other properties are greatly improved. It can be widely used in chemical industry, aerospace, military, household, In various fields such as hospitals, it can be made into lamps, dials, telescopes, observation holes for washing machines, microwave oven trays, solar water heaters and other products.

Cutting principle of glass materials

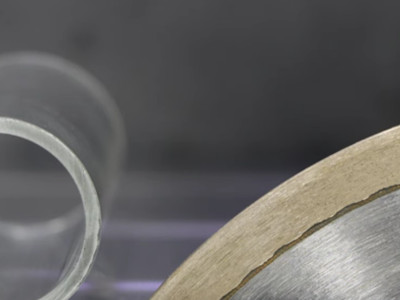

The cutting of glass utilizes the brittleness and residual stress of the glass to create a score at the cutting point to cause stress concentration. Under the action of external force, the fracture line spreads along the direction of the stress, thereby achieving the purpose of cutting the glass. For glass plates and glass tubes that are not too thick, diamond cutting blades or other tough tools can be used to cut and break them directly.At present, there are two kinds of processing of precision glass tubes: one is high temperature with hot processing technology, and the other is precision mechanical shaping with cold processing technology.

Moresuperhard's diamond cutting wheel for precision tubes

Moresuperhard offers resin diamond cutting discs and metal diamond cutting discs specifically for cutting in the glass industry. It can be used to cut glass optical devices such as quartz glass, K9 glass, coated glass, etc. It can also be used to cut various glass tubes, glass spouts, high borosilicate glass tubes, capillary glass tubes, quartz glass, and crystallized glass.

Advantages of cold diamond cutting disc for glass tubes

1. Good self-sharpening, sharp cutting, high efficiency, easy to achieve large cutting depth and large feed

2. The bonding agent is elastic and can improve the processing quality and workpiece finish.

3. Few or no trimming times required

4. The cutting edge is smooth and burr-free

When cutting long glass tubes, both ends of the glass tube must be fixed to avoid edge explosion.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088