Graphite is a common non-metallic material, black in color, with high and low temperature resistance, good electrical and thermal conductivity, good lubricity and stable chemical properties; it has good electrical conductivity and can be used as an electrode in EDM. Compared with traditional copper electrodes, graphite has many advantages such as high temperature resistance, low discharge consumption, and small thermal deformation. It has shown better adaptability in the processing of precision and complex parts and large-size electrodes, and has gradually replaced copper electrodes as the mainstay of EDM. Mainstream of machining electrodes. In addition, graphite wear-resistant materials can be used under high-speed, high-temperature, and high-pressure conditions without lubricating oil. Many equipment widely use piston cups, sealing rings, and bearings made of graphite materials.

Graphite is a brittle material with a heterogeneous structure. Graphite cutting is achieved by generating discontinuous chip particles or powder through the brittle fracture of the graphite material. The formation process of graphite chips is roughly when the cutting edge of the tool comes into contact with the workpiece, the tool tip is squeezed and broken, forming small chips and small pits, and a crack is generated. The crack will extend to the front and bottom of the tool tip, forming a fracture concave. Pit, part of the workpiece is broken due to the advancement of the tool, forming chips.

1. Machining. The machining of graphite materials usually refers to the use of cutting tools to process the material, such as milling, turning, drilling, etc. Due to its simple operation and high processing precision, machining can meet higher process requirements.

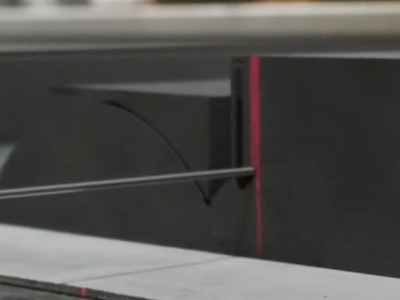

2. Wire cutting. Wire cutting is a high-precision and efficient processing method, suitable for processing thin sheets, small holes and details of graphite materials. Cutting is completed through discharge between the electrode and the workpiece, and different processing effects are achieved by adjusting process parameters.

3. Grinding wheel processing. This processing method is suitable for polishing or rough cutting of graphite materials. This is achieved by grinding the surface of the material with a grinding wheel.

4. Electrical discharge machining. Electrical discharge machining is a processing method that processes metal materials through high-voltage discharge. For non-metallic materials such as graphite, its wear resistance and corrosion resistance make it an ideal candidate for EDM.

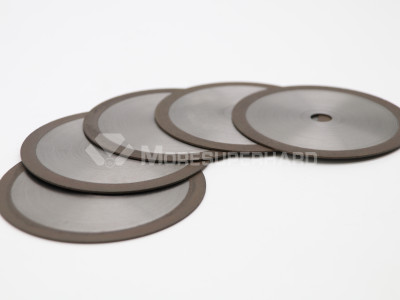

5.Diamond cutting wheel.Diamond cutting wheels are widely used for cutting hard materials like ceramic,graphite,silicon etc.

Graphite block cutting case

Resin diamond cutting wheel

1A1R D150*H25*T1.2*X7

Grain sizes:D91

Cutting graphite without coolant

High cutting efficient and long services life

Moresuperhard provide quality diamond cutting wheel for precision cutting hard materials like ceramic,carbide,graphite,silicon etc.Moresuperhard supply different bond diamond cutting wheel like resin bond diamond cutting wheel,electroplated diamond cutting wheel and metal bond diamond cutting wheel.We have many customers from all over the world.Welcom your inquire.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Moresuperhard provides high-precision copper wheel electrodes for EDM machining of PCD tools, including shaping, slotting, and edge finishing. Using Moresuperhard's copper wheel electrodes enhances machining accuracy, reduces chipping, extends tool life, and improves production efficiency.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088