How to perform continuous dressing in creep feed grinding

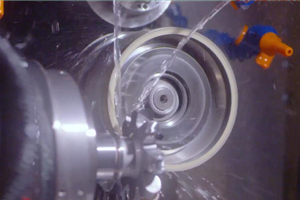

The so-called continuous dressing refers to the method of reshaping and sharpening the grinding wheel while grinding. When the continuous dressing method is used, the diamond dressing roller is always in contact with the grinding wheel. In order to realize the dynamic process of continuous dressing grinding wheel and continuous compensation in the grinding process, a special continuous dressing grinder must be used.

The initial diameter of the grinding wheel is ds1, the diameter of the workpiece is dw1, and the diameter of the diamond dressing roller is dr. During grinding, if the radius of the workpiece becomes smaller at the speed of vfr, the wheel should be at the speed of v2 = vfr + vfrd due to the continuous dressing When cutting into the grinding workpiece, the dressing wheel should be cut into the dressing wheel at a speed of v1 = 2vfrd + vfr, so that the position of the dressing wheel and the wheel changes. Therefore, the grinding machine that continuously dresses the grinding wheel must be able to adjust these geometric parameters.

The advantages of continuous dressing are many, such as:

1) The grinding time which is just equal to the dressing time is subtracted, which improves the grinding efficiency;

2) The maximum grinding length no longer depends on the wear of the grinding wheel, but on the available grinding length of the grinding machine;

3) The specific grinding energy can be reduced, the grinding force and grinding heat are reduced, and it is stable during the grinding process.

<< Prev Article:Production process of diamond powder

<< Next Article:Creep Feed Grinding

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220