The Radius could reach R0.002

Overall waviness: 0.014μm

Surface quality could meet: 1nm

The included angle: 15 degree is OK

Diamond cutter for the infrared lens

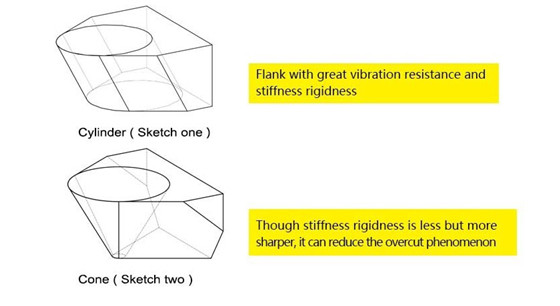

Sharp cutting edge, the degree of finish can reach to 5nm on the work piece surface, overlong using life. Besides common specification, the least arc customization parameter we can accept is 2μm, the included angle 15 degree, the tools have 2 clearance angle in cylinder(Sketch one) and cone(Sketch Two)

<< :Application of PCD tools in automobile piston machining

<< :PCD reamer for cylinder head valve guide and valve seat processing

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088