Application:

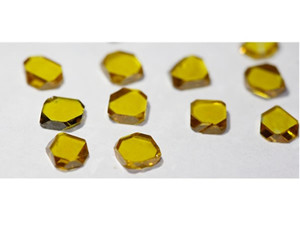

Mono-crystalline diamond die blanks can be used in hot drawing and cold drawing of various metal wires, with high quality polished surface and long service life.

Descriptions and Features:

Monocrystalline diamond not only has the similar performance with natural diamond, but also has other characteristics, such as: high hardness, good wear resistance, high strength, perfect thermal conductivity, low friction coefficient with nonferrous metals, good anti-caking, high corrosion resistance and excellent chemical stability. This kind of diamond die blank plays a important role in machine processing field, especially precision processing, and it is being used more and more widely.

Specifications:

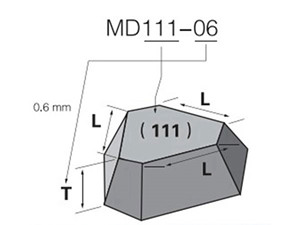

Monocrystalline diamond die MD111 blanks are categorised by their thickness in millimetre (see table). The other major product dimension is defined by its inscribed circle diameter. Die piercing can be carried out by laser or ultrasonic machining techniques.

|

Product Nomenclature

|

Nominal thickness(mm) |

Thickness tolerance

(mm) |

Minimum inscribed

Circle diameter(mm) |

|

MD111-05 |

0.5 |

0.46-0.55 |

0.6 |

|

MD111-06 |

0.6 |

0.56-0.66 |

0.7 |

|

MD111-07 |

0.7 |

0.66-0.75 |

0.8 |

|

MD111-08 |

0.8 |

0.76-0.85 |

0.9 |

|

MD111-09 |

0.9 |

0.86-0.95 |

1.0 |

|

MD111-10 |

1.0 |

0.96-1.05 |

1.1 |

|

MD111-11 |

1.1 |

1.06-1.15 |

1.2 |

|

MD111-12 |

1.2 |

1.16-1.25 |

1.3 |

|

MD111-13 |

1.3 |

1.26-1.35 |

1.4 |

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088