The effect of proper grinding wheel on grinding efficiency

In the grinding work, the main factors that affect the grinding efficiency and quality are: grinding machine equipment, grinding wheel, operators.All three are very important, but the quality and performance of the grinding wheel should be given priority.The reasons are as follows:

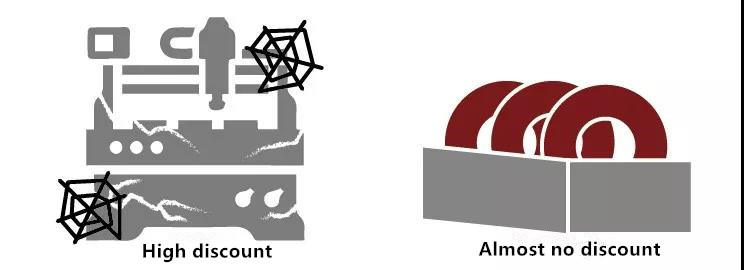

1.Grinding machine cost

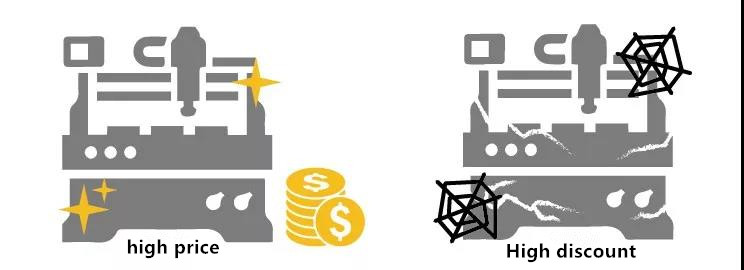

Good grinder, not only can improve the quality of grinding, productivity can also be improved.So, good equipment is a basic investment!However, has the current grinding efficiency reached its maximum value?Maybe a lot of people haven't noticed.

In addition, good equipment to invest in the amount of large, good times, natural is a single tool;But when times are bad, there are idle problems.Especially in today's environment, the business cycle is extremely volatile, often not orders are not connected;It's almost no single extreme difference.

It is not that we should not invest in better grinding machines, but we should first think: is the current production efficiency reached the optimal level of grinding machine capacity?

2.Operating personnel costs

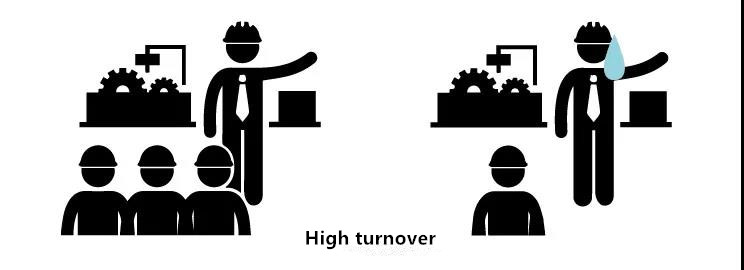

Compared with other manufacturing operators, grinding operators often need more time to train and cultivate.

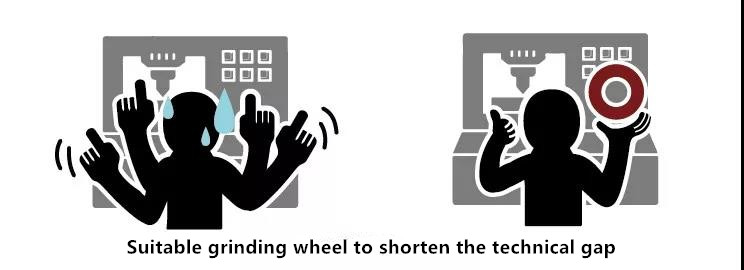

And hidden cost differences are often overlooked.Experienced and skilled grinders may earn 2 to 3 times the salary of beginners.However, processing efficiency and quality may be 20~30 times, or even higher!This hidden cost gap, add up is very amazing!

And if we use a better and more suitable grinding wheel, it is equivalent to the car replaced with a better tire, not only speed up, but also more fuel efficient!In this way, can simply improve the grinding efficiency and quality!

However, the cost of replacing a good grinding wheel is also increased?

Indeed, the price of a good grinding wheel will be higher, but, unlike grinding machines, grinding wheel is a variable cost.Facing the environment of huge fluctuation, the flexibility of investment grinding wheel is higher.

If you buy a good grinding wheel, there will be no extra cost if you don't use it.And buy expensive equipment, high depreciation expense, not because do not use the equipment, do not produce.

Greatly reduce the hidden cost waste of experience gap.

In addition, the grinding learning curve is very long and it is difficult for new recruits to get a sense of accomplishment, which is also one of the main reasons for the difficulty in recruitment and high mobility.

If you can improve the excellent weapon - grinding wheel, you can effectively reduce the learning curve, and reduce the turnover rate.The stability of the quality of production, as well as the cost reduction, has a huge positive impact.

Therefore, although grinding wheel is only a factor affecting grinding work, the use of high-quality grinding wheel can play the following muliple effects:

(1) improve the quality of grinding efficiency

(2) increase the flexibility of capacity

(3) reduce fixed capital investment

(4) reduce the mobility of grinding personnel

(5) improve the grinding personnel's technical ability

The use of high-quality grinding wheel, can have such an obvious twice the result with half the effort, so, for the selection of grinding wheel, we should put more effort.

<< Prev Article:Petroleum industry

<< Next Article:Quality Control For Resin Diamond Wheel for Cylindrical Grinding

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220