Customer profile

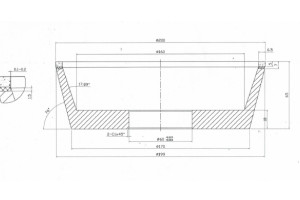

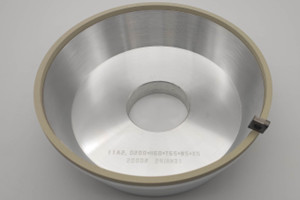

The customer has a Coborn PG series grinding machine for grinding PCD (polycrystalline diamond) tools and single crystal tools. At present, we first start our cooperation by grinding PCD blades. After communicating with the customer, we learned that the equipment used by the customer is KANEHIRA RTG3800, the workpiece is a PCD blade, the grinding wheel size is 11A2, and the specification is D200H60T65W6X5. A transition layer of copper or plain grinding is required between the abrasive layer of the grinding wheel and the base. After communicating with the customer, the grinding wheel ring width was changed to 5mm, and they accepted that there would be no transition.

Moresuperhard provide grinding paraments guidance for customer

However, the customer's current processing parameters caught our attention. The feed rate set by the customer is 0.1mm/min, which is a relatively large feed rate in rough machining. Considering the bearing capacity of the grinding wheel and workpiece, as well as the 2000# grit grinding wheel ordered by the customer, we suspect that the customer may currently be in the rough machining stage. However, this is inconsistent with the grit size of the grinding wheel used, since 2000# grit is usually used for precision machining. Therefore, we recommend that customers adjust the feed amount to within 1 wire and try starting from 5μm to meet the requirements of precision machining.

The importance of precision machining

Precision machining can not only improve the surface quality and dimensional accuracy of the workpiece, but also reduce the residual stress of the workpiece, extend the service life of the tool, and improve processing efficiency. By reducing the amount of feed, the heat and cutting force during processing can be reduced, the roughness of the workpiece surface can be reduced, and the processing accuracy can be improved. In addition, precision machining can also reduce wear in the cutting area, extend the service life of grinding wheels and tools, and reduce processing costs.

Moresuperhard is always focus on help you solve grinding problems

To sum up, by optimizing the machining plan and transforming from rough machining to precision machining, the machining efficiency and workpiece quality can be improved, meeting customer needs and improving the effectiveness of cooperation.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088