Gear shaft refers to a mechanical part that supports rotating parts and rotates with it to transmit movement, torque or bending moment. It is generally in the shape of a metal round rod, each section can have different diameters, and the rotating parts in the machine are mounted on the shaft.

01 Gear shaft processing requirements

(1) Gear shafts are the main basic transmission components and consumable parts of automobiles and machine tools, and their quality directly affects the noise, stability and service life of automobiles and machine tools.

(2) The gear shaft is mainly subjected to alternating loads, impact loads, shear stress and contact stress. The shaft is prone to cracks and the teeth are prone to wear. Therefore, the core of the gear shaft is required to have a certain degree of strength and toughness, a higher fatigue limit and multiple impact resistance.

(3) The surface of the gear shaft should also have a certain degree of hardness and wear resistance. In order to obtain a good service life, gears and gear shafts are often carburized and quenched.

(4) The difficulty in hard turning of gear shafts is that there are intermittent cutting in some positions, such as small holes on the end of the gear or key grooves in the inner hole. The hardness is high and there are strong interruptions, which will easily cause chipping and rapid wear of the tool. And other issues.

02 , The advantages of More SuperHard PCBN tools for machining gear shafts

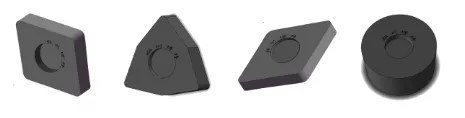

The More SuperHard PCBN blade is made by advanced production technology and production equipment. It has high hardness, good red hardness at high temperature, and is suitable for cutting in strong, weak and continuous environments. In the subdivision field of gear shaft processing, More SuperHard PCBN blades have been verified by the market. They have the characteristics of strong versatility, good wear resistance, high surface finish after processing, reducing tool change time, greatly improving production efficiency, etc., replacing hard materials. The advantages of alloy tools are obvious.

03,More SuperHard PCBN tool processing gear shaft case

|

Inner hole finishing |

||

|

Factory |

Abroad |

More Super Hard |

|

Workpiece & Material |

Shaft gear (200GrMoTi HRC58-63) |

|

|

Processing part |

Inner hole |

|

|

Cutting tools & Material |

CNGA120408 creamic |

CNGA120408 CBN |

|

Depth of cut ap(mm) |

0.5 |

|

|

Linear velocity V(m/min) |

150 |

|

|

Feed f(mm/min) |

0.08 |

|

|

Tool life |

60 |

164 |

|

Roughness |

Ra1.2 |

Ra0.8 |

|

End face finishing |

||

|

Factory |

Abroad |

More Super Hard |

|

Workpiece & Material |

Shaft gear (200GrMoTi HRC58-63) |

|

|

Processing part |

Inner hole |

|

|

Cutting tools & Material |

CNGA120408 CBN |

CNGA120408 CBN |

|

Depth of cut ap(mm) |

0.2-0.3 |

|

|

Linear velocity V(m/min) |

80 |

120 |

|

Feed f(mm/min) |

0.08 |

0.12 |

|

Tool life |

200 |

200 |

|

Roughness |

Ra1.6 |

Ra1.6 |

|

Efficiency |

1 |

2.25 |

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Moresuperhard provides high-precision copper wheel electrodes for EDM machining of PCD tools, including shaping, slotting, and edge finishing. Using Moresuperhard's copper wheel electrodes enhances machining accuracy, reduces chipping, extends tool life, and improves production efficiency.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088