News

Home / News > PCD Micro Drills

Application

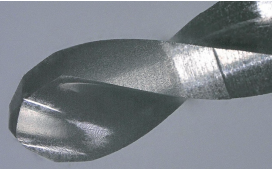

Suitable for monocrystalline silicon and quartz Ceramics, etc. are fragile and difficult to process Material drilling

Advantage

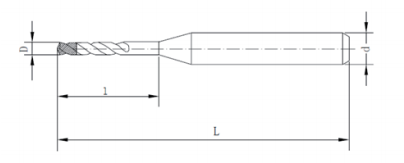

-φ0.1mm~φ2.0mm Any size according to customer needs

-Can be customized Fast product within 5~10 days Delivery capability

-This product has been large and stable Supply to Japanese and Korean companies

<< :Polycrystalline diamond product series

<< :High-efficiency machining plan for aerospace titanium alloy structural parts

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088