Case Studies - Case I

|

Workpiece |

Valve Seat |

|

Cutting inserts |

PCD – CCGW09T304Q5 |

|

Workpiece Materials |

Aluminum Alloy |

|

Cutting Parameters |

Vc=500m/min |

|

Ap=1.2mm |

|

|

f=0.2mm/r |

|

|

Cutting Method |

Light Interrupted

Semi-finishing |

|

|

|

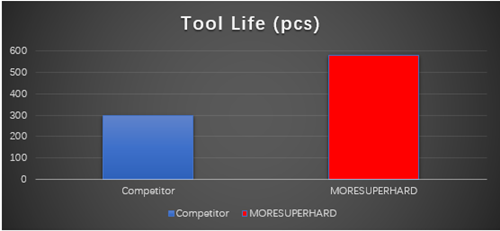

Comparison

Case II

|

Workpiece |

Mould |

|

Cutting inserts |

PCD – CCGW09T304Q5 |

|

Workpiece Materials |

20HRC

Aluminum Alloy |

|

Cutting Parameters |

Vc=480m/min |

|

Ap=0.15mm |

|

|

f=0.02mm/r |

|

|

Cutting Method |

Continuous Finishing |

|

|

|

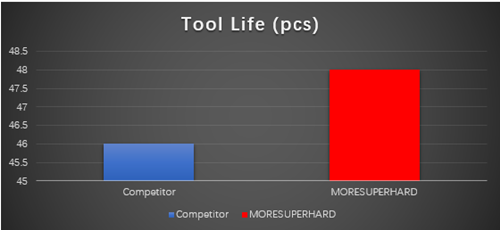

Comparison

Diamond wafers have great potential in high-end fields such as quantum computing, microwave power devices, and semiconductor lasers due to their ultra-high hardness, excellent thermal conductivity, and wide bandgap properties.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088