PCD/PCBN tools has three basic forms: integral type, full section type and tip type. The larger and thicker PCBN integral cutter has good wear resistance and impact resistance. Good wear resistance and impact resistance of cutting tools are the key means of processing cast iron materials containing less than 10% ferrite. The improvement of tool wear resistance and impact resistance is particularly important for the automobile industry to process alloy cast iron parts.

When roughing alloyed cast iron, the tool must undergo discontinuous cutting caused by surface cracks, residual sand and other original surface discontinuities left over from the casting process. Good wear resistance also plays a very big role in finishing, especially for the workpiece containing chromium 28% ~ 30% and hardness between 68 ~ 70HRC.

The solid PCBN inserts has multiple cutting edges on both sides, thus reducing the tool cost per production part. The cross section is 4.76mm thick, which is 3.17mm thicker than conventional cutters, allowing the blade to mount reliably on standard gasket carbide handle slots.

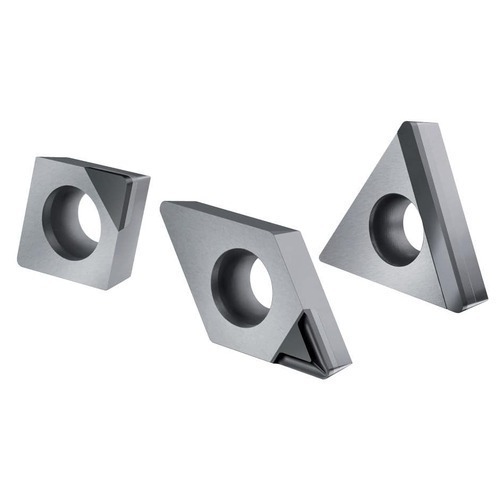

PCBN inserts are also available in full section and tip shape. The full section blade has a complete PCBN top surface, sintered on a hard alloy substrate, providing multiple cutting edges on only one side of the blade, which is less expensive than the whole blade. The tip blade is a PCBN blade welded to a corner of the carbide base. The tip blade is either a single cutting edge or a double cutting edge. Most PCBN blades used today are tip shaped. Both full-section and point-shaped inserts are manufactured to industry standard sizes and can be mounted in standard bar inserts and milling slots as integral inserts.

The PCBN cutter is more suitable for machining hard parts:

The tool made of PCBN is most suitable for cutting hard parts. In fact, the lower limit of hardness for machined parts is 45HRC. If PCBN tool is used to process parts with hardness less than 45HRC, tool marks will be produced.

In rough machining, the maximum cutting depth of white iron and other hard high chromium iron is about 4.76mm in the range of 4.76 ~ 6.4mm with the overall PCBN tool cutting. The maximum cutting depth of non-alloy pure cast iron is 6.4mm, and the cutting speed ranges from 107 ~ 122m/min for high chromium iron to up to 2134 /min for gray cast iron. All processing with PCBN tools, all require the use of very good rigidity tools, fixtures, spindles and machine tools.

Proper PCBN tool finishing cutting speed varies significantly with the material of the workpiece, the height of the material, and the size and shape of the part. For example, you can process hardened steel with a rockwell hardness of 60 to 62HRC and achieve a cutting speed of 183m/min at a cutting depth of 0.51mm. The lower surface roughness can be machined with feed rate of 0.05 ~ 0.1 mm/r. The harder the material, the higher the cutting speed. However, cutting speeds greater than approximately 198m/min will result in excessive wear. Ordinary cast iron can be machined at very high cutting speeds.

Tool-tip PCBN tools are economical and reliable for both roughing and finishing. But in this occasion requires the use of integral tool and full - section tool. A typical example is a rough boring of the middle part of a cylinder liner with cast burrs. Burrs on the workpiece can eventually cause the PCBN blade to deviate from the correct position when it is machined with a tool-tip tool at very precise depth of cut. Powerful integral and full section PCBN tools eliminate this problem. Both integral and full section tools can be reground, thus extending tool life. For the best cost effectiveness of the monolithic tool, the cutting edges on both sides of the monolithic tool should be used.

Currently, the biggest area of development for PCBN tools is in high-hard cutting -- the finishing of automotive engine alloy steel parts such as gears, shafts and bearings with a rockwell hardness of 60 to 65HRC. Traditionally, such parts could only be made by grinding. Moreover, the dimensional tolerance of parts is very small, and the surface roughness is very fine. The high hard cutting allows the same results to be achieved on a CNC lathe for half the cost of machining the same quality parts on a CNC grinder, and the maintenance cost of the lathe is lower.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088