Why PCD tools are not suitable for rough processing?

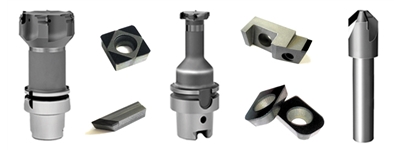

Polycrystalline diamond (PCD) tools for processing aluminum workpieces have the advantages of long tool life and high metal removal rate. But the disadvantages is expensive and high processing cost. When processing various newly developed aluminum alloy materials (especially high-silicon-content composite materials), in order to optimize productivity and processing quality, the grade and geometric parameters of PCD tools must be carefully selected to meet different processing requirements. Its applicability is restricted by different workpiece material.

When processing aluminum alloy materials, the work life of carbide tools is only about 5% than PCD tools, the rough cutting speed of carbide tools is about 120m/min. PCD cutting speed can reach 360m/min.

Tool manufacturers recommend using fine-grained (or medium-grained) PCD for silicon-free and low-silicon aluminum alloy materials, and rough-grained PCD for high-silicon aluminum alloy.

<< Prev Article:PCD forming tools power sytem (cylinder head)

<< Next Article:Polycrystalline diamond (PCD) tool for automotive piston

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220