Vitrified diamond for PCD & PCBN tools

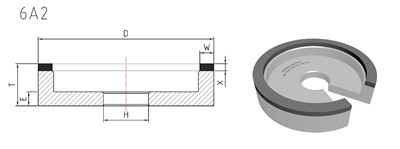

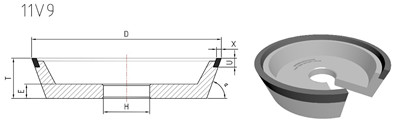

Model 6A2, 11V9 can be used to grinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, milling cutter, reamer, drill and regrinding, etc.

Commonly size:

|

Grain Size |

Machining Type |

Application |

|

W40(500# D35) W28(D20) |

Rough |

Regrinding a blade edge profile and sharpening of much worn inserts |

|

W20 (800# -1000#, D20) |

Universal |

Standard grain size also can get a high sharpening efficiency, good quality surfaces |

|

W10 (1500# D15A) W7 (2000# D15B) |

Finish |

Finishing grinding - getting a very good quality of machined surfaces |

|

W5 (3000# D7) W3.5 (4000# D3) |

Super Finish |

Super finish grinding - getting a brilliant quality of machined surfaces |

Cylindrical grinding for PCD tools

Cylindrical diamond grinding wheel is used for PCD reamers grinding. The PCD tools in automotive industry include PCD profile cutters, PCD reamers and PCD milling cutters. It enjoys high grinding power, long working life, good surface quality, strong sharpness, high self-sharpening, good surface finish after grinding. High efficiency, less dressing time, and stable quality.

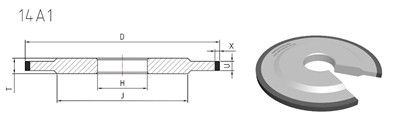

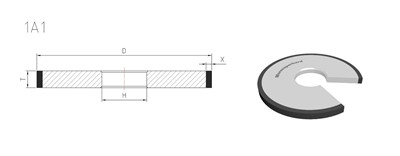

Peripheral Grinding for PCD CBN indexable inserts

Mainly used for precise edge grinding of indexable inserts, tungsten carbide inserts, ceramic inserts, CBN inserts.

Materials of workpiece: tungsten carbide, ceramics, metal ceramic PCD/ PCBN inserts, etc.

Compatible Machines of MORESUPERHAD Peripheral Diamond Wheels:

1.AGATHON:

400 Series: 400 PENTA, 400COMBI, 400SEMI, 400PERI.

350 Series: 350T B, 350COMBI

250 Series: PA250

AGATHON 400 PENTA 5-axis insert grinder is a fully automatic grinding center of the latest generation providing increased efficiency for insert production, the wheels used on AGATON are up to 400mm diameter. Which can grind most tool geometries with flexible clamping system. AGATHON laser machine can reduce the PCD processing time when make tool insert rough cutting, which can take place the rough grinding sometimes.

2.WENDT:

400 Series: WAC715, WAC735

350 Series: WAM336

3.WAIDA

AP460E

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088