Development Trend of CNC Tool Grinding Processing

As the network application of CNC machine tools becomes more and more widespread, the high reliability of CNC technology has become the goal pursued by manufacturers. In order to meet the needs of long-term unmanned operation, CNC systems and CNC devices must have high reliability. As we all know, the grinding of high-precision tools is increasingly becoming a widespread demand in the market, which also puts forward new requirements for the high-speed performance of grinders and the stable grinding performance of diamond and CBN grinding tools.

How to ensure tool quality while improving the stable and efficient grinding of carbide tools? This places higher and higher requirements on the rigidity and grinding performance of the grinding wheel. Moresuperhard has always been committed to the development and manufacture of efficient and stable grinding wheels. Provide customers with comprehensive grinding solutions.

1.Applications of resin cnc grinding wheel

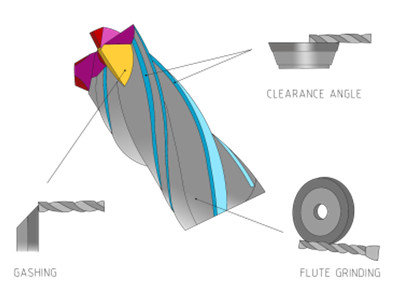

Resin bonded diamond/CBN grinding wheels are used for grooving, relief grinding, peripheral and end tooth processing and grinding of CNC tools such as solid carbide and high-speed steel drill bits, milling cutters and reamers.

2.Characteristic of Resin bond cnc grinding wheel

*Suitable for high-efficiency grinding processing with rapid feed

*Good wear resistance and shape retention

*It has good self-sharpening properties, generates less grinding heat, reduces burns on the workpiece, and meets the high-precision requirements of the tool.

*No clogging, easy to trim, extend the trimming cycle and reduce processing costs.

*The grinding workpiece has consistent edge quality and high smoothness, which ensures stable quality when processing downstream products.

1.Dressing wheel for CNC grinding wheel

Dressing wheel for resin cnc grinding wheel:Green silicon carbide dressing wheel or aluminum oxide dressing wheel

Dressing Grain size: 80-120 mesh, also depends on the grinding wheel size

Dressing wheel Hardness:E, G, H, J/K

Grinding wheel linear speed: 2-6m/s

Dressing wheel linear speed: 8-25m/s

Swing speed: 200-1000mm/min

Rough dressing: 0.02-0.08mm/time

Fine dressing: 0.005-0.02mm/time

Use coolant whenever possible When dressing fine-grained grinding wheels, the feed rate should be reduced (In addition, increasing the grinding wheel speed or reducing the feed speed can improve the surface finish)

2.Dressing sticks for CNC grinding wheel

Use soft and fine-grained oilstone for sharpening, and grind tightly against the grinding wheel until the diamond on the surface of the grinding wheel is exposed.

Abrasives of oilstone:Alumina

Recommended particle size: 240-320

Recommended hardness G or H

Precautions for using dressing olistone:Coolant soaked oil stone strips; During sharpening, the rotation direction of the diamond grinding wheel should be consistent with the grinding rotation direction;Dressing should be done after dressing or any time the wheel becomes clogged and creates more load.

Moresuperhard always focuses on R&D and innovation. Moresuperhard is committed to providing better quality products to customers in the CNC tool industry, helping customers improve grinding efficiency and reduce overall costs by using Moresuperhard's CNC grinding wheels.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088