In recent years, with the rapid development of aerospace, medicine, automobile and electronics industries, efficient and low-cost micro-hole processing technology has become a research hotspot in the field of mechanical processing.

What is micro drill tool?

Tools used for drilling micro holes, referred to as "micro drills",It is the core factor that determines the ability to drill micro holes.When the diameter of the micro drill is less than or equal to 1 mm, the appearance and geometric structure of the drill bit are obviously different from conventional drill bits, such as no cutting edge, no drill body gap depth, and larger drill core thickness. In addition, the main failure mode of micro drills with a diameter of 1 mm or less during processing is the breakage of the cutter body. Drill bits with larger diameters will have more obvious wear characteristics before breaking and failing. Therefore, in traditional machining, using 1 mm diameter as a standard can clearly distinguish the above changes, so holes with a diameter of less than or equal to 1 mm are defined as micro holes, correspondingly The hole machining tool is called a micro drill.

Why use PCD material to make micro drill cutters?

High-performance micro-drill tool materials must have the following characteristics: high hardness (normal and high temperatures), good wear resistance, good toughness, and high stiffness. With the support of the above material properties, microdrills can withstand the deformation resistance of the tool/workpiece interface and the thermal stress of the tool/chip interface, control tool wear, slow down the increase in the cutting edge arc radius, suppress tool deformation and fracture failure, thereby effectively extending the Tool life.

PCD Polycrystalline diamond is composed of a certain proportion of natural or synthetic diamond powder and binders (containing cobalt, nickel and other metals) at high temperature (1000~2000℃) and high pressure (50000~100000 atmospheres) A super-hard material made by sintering. Due to the addition of binding agents, bonding bridges with TiC, SiC, Fe, Co, Ni, etc. as the main components are formed between the diamond crystals. The diamond crystals are embedded in the bonding bridge skeleton in the form of covalent bonds, so the material has extremely high It has good hardness and wear resistance, good thermal conductivity and low friction factor, and is widely used in the field of cutting processing.

PCD Micro Drill Tool Manufacturing Technology

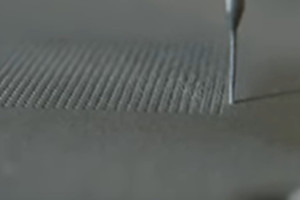

PCD micro drills mostly use laser cutting and wire EDM technology to cut the PCD pre-slabs, and then use laser engraving or profiling electrode EDM grinding to shape the tool geometry. Finally, a high-precision grinding wheel is required. Or use free abrasive grinding to remove the heat-affected layer on the surface of the PCD material, improve the surface finish of the tool, and sharpen the cutting edge. Therefore, micro-drill manufacturing processes, including grinding, EDM, and laser processing, all have their own scope of application and technical advantages, and they need to be selected according to the needs of micro-drill manufacturing.

Moresuperhard provide solid pcd blanks,precision grinding wheel and polishing liquid for machining PCD micro drill ,more details please contact us freely.

<< :Application of ceramic diamond grinding wheels in the abrasives industry

<< :Application of PCD cutting tools in woodworking industry

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088