What is superhard cutting tools?

Superhard tools are cutting tools that use materials with exceptional hardness and wear resistance, often beyond that of common tool materials like carbide or high-speed steel. Diamond and cubic boron nitride (CBN) are the most common superhard materials used in cutting tools due to their extreme hardness, toughness, and chemical stability. Superhard tools are more expensive than traditional cutting tools but can offer significant benefits in terms of longer tool life, higher cutting speeds, and improved surface finish on the machined parts. They are commonly used in the machining of high-strength and abrasive materials such as hardened steels, cast irons, and composites.

Standard PCD/PCBN inserts

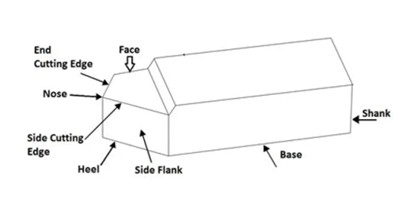

What is cutting edge of tools?

The part where the rake face and the main flank intersect is the main cutting edge; there is also a secondary cutting edge on the insert, which is where the rake face and the secondary relief corner intersect; the tip part is the main cutting edge and the secondary Where the cutting edges intersect.

How to process the edge of cutting tools?

1.Grinding-PCD/PCBN grinding machine

2.Laser-using fiber laser grinding machine

3.EDM-wire cutting machine

Laser machining and EDM maching are used in rough machining of cutting edge.In order to achieve high-precision edge grinding, it is necessary to use a high-precision grinding machine with a diamond grinding wheel for processing。

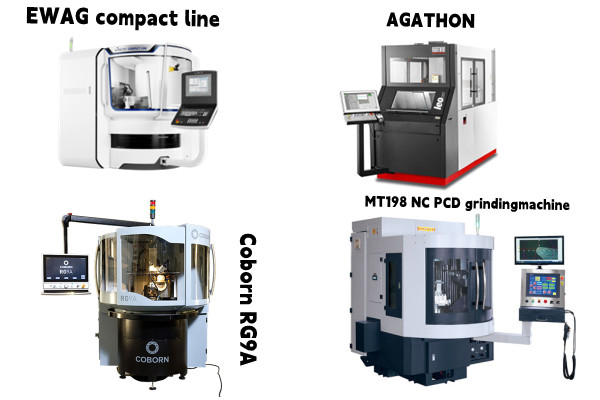

Some famous precision grinding machine from all over the world

COBORN ,AGATHON,EWAG,MT198 NC

Moresuperhard provide MT198 nc grinding machine for PCD/PCBN tools grinding.

- MT-198NC spindle can be raised and lowered, B axis braking system and MPG handwhell provides added convenience in machine running test when production of special tools.

- 198NC PCD PCBN Tool Grinder, is a versatile machine, perfectly suited for manufacture and resharpen high-quality tools.

- The high-end machine, MT-198 has creative technologies to make it convenience to machine a wide range of special tools such as, spindle can be vertical movement, B axis braking system and MPG handwheel for easy setting and running test.

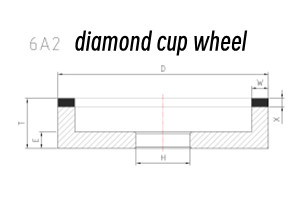

What kind of grinding wheel is used for PCD/PCBN cutting tool edge grinding?

6A2 vitrified diamond grinding wheel is always used for grinding/sharpening PCD/PCBN inserts.6A2, 150D * 40T * 40H * 3/5/10/15/20W * 10X

6A2, 150D * 40T * 40H * 3/5/10/15/20W * 10X

How to choose the right grinding wheel size in the grinding process?

| 6A2 vitrified diamond grinding wheel for grinding PCD /PCBN tools | grain sizes |

| Rough grinding | W40 |

| Semi-fine grinding | W20,W14 |

| Fine grinding | W10,W7 |

| Ultra-fine grinding | W5,W3.5 |

Common problems in PCD/PCBN tools edge grinding

1.The grinding wheel is noisy

2.Large edge chipping

3.Uneven workpiece quality

4.Short grinding wheel life

Have you ever faced problems like these when you process PCD/PCBN tools?Moresuperhard is always focus on providing PCD/PCBN tools grinding solutions.Moresuperhard provide PCD/PCBN blanks for cutting tools,

laser cutting machine for cutting pcd/pcbn blanks,brazing machine for welding pcd/pcbn inserts,vitrified/resin diamond grinding wheel including cup wheel,peripheral diamond grinding wheel,cylindrical diamond grinding wheel suit your grinding machine ,CNC and manual pcd grinding machine all can we provide.Dressing solutions from Moresuperhard also available.

If you have any pcd/pcbn grinding needs,please contact us freely.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088