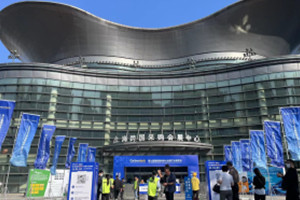

Carbontech2023 carbon materials industry exhibition was successfully held in Shanghai from November 1-3! Carbontech2023 carbon material industry exhibition has adopted a new exhibition area plan, including carbon fiber and carbon/carbon exhibition area, energy storage battery exhibition area, carbon nanomaterials/porous carbon exhibition area, graphene exhibition area, instrument and equipment exhibition area and diamond/cultured diamond exhibition area.

Introduction to carbon materials

Definition of carbon materials

Carbon material is a material composed of carbon elements. Carbon is one of the most common elements on earth, with abundant resources and diverse forms. Carbon materials can be divided into three major categories: amorphous carbon materials, crystalline carbon materials and nanocarbon materials. Amorphous carbon materials include carbon black, activated carbon, etc., which have large specific surface area and adsorption capacity. Crystalline carbon materials include graphite, diamond, etc., which have good electrical and thermal conductivity. Nanocarbon materials include carbon nanotubes, graphene, etc., which have unique structures and excellent mechanical properties.

Types of carbon materials

1.Diamond

Diamond is commonly known as "diamond", which is what we often call diamond. It is a mineral composed of carbon and an allotrope of carbon. Diamond is the hardest substance naturally occurring in nature.

Properties: High thermal conductivity, low coefficient of thermal expansion, low coefficient of friction, high hardness, high transparency in visible and infrared light, high refractive index, chemically and radioactively inert.

Application areas: jewelry, cutting tools, abrasives, thermal probes in adverse environments, radioactive detectors, pressure sensors, fluorescence intensifiers, optical windows, micro-mechanical components, and high-density, energy electronic components, etc.

2.graphite

Properties:Layered structure, strong bonding force, high hardness and strength, good electrical conductivity and thermal stability

Application areas:Special graphite will be increasingly widely used in new energy vehicles, aerospace, nuclear power and other high-tech fields, becoming an important strategic resource supporting the development of high-tech.

3.carbon fiber

Carbon fiber (CF) is a new type of fiber material with high strength and high modulus fiber containing more than 95% carbon. It is made of organic fibers such as flake graphite microcrystals stacked along the axial direction of the fiber. , microcrystalline graphite material obtained by carbonization and graphitization.

Application fields: aerospace, aviation, automobiles, electronics, machinery, chemicals, textiles, sports equipment and leisure products

4.silicon carbide

Silicon carbide is one of the third-generation semiconductor materials. Its dielectric breakdown strength is about 10 times that of silicon. It is mainly used to produce power semiconductor devices and is suitable for high-temperature, high-voltage, and high-power scenarios.

5.carbon nanotubes

Carbon nanotubes, also known as Bucky tubes, are seamless hollow tubes formed by curling graphite sheets. They are also representative one-dimensional carbon nanomaterials.In recent years, in the field of flexible electronic devices, carbon nanotubes have been rapidly developed in applications in this field due to their good flexibility and ease of large-area preparation, such as strain sensors, pressure sensors, gas sensors and temperature sensors, etc., for Development of wearable smart products

Carbon material is a very important material with a wide range of application prospects. At present, carbon material has been widely used in electronics, automobiles, aerospace, new energy and other fields. In the future, the application fields of carbon materials will continue to expand and be used in more industries. The development of carbon materials will also be driven by technology.

Moresuperhard closely follows the development trend of the industry and established a special group for carbon material processing. In the future, Moao will continue to provide more cutting, grinding and polishing solutions for your carbon material workpiece processing.Looking forward it.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Learn how to choose the right PDC cutters for deep and hard rock formations. Explore diamond thickness, thermal stability, impact toughness, cutter geometry, and bit design.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088