Techniques for outer round grinding of diamond grinding wheels

Diamond grinding wheel with diamond abrasive as raw material, respectively, with metal powder, resin powder, ceramics and electroplating metal as a binding agent, the middle has a hole in the round cementing abrasive called diamond grinding wheel (alloy grinding wheel). In general, there are four techniques for the outer round grinding of diamond grinding wheels, which are described separately below.

.png)

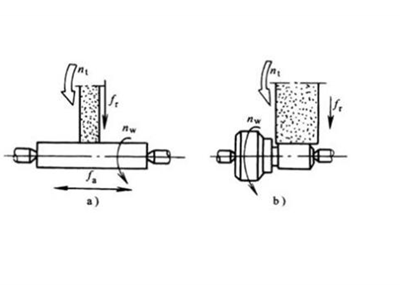

1.the vertical grinding of diamond grinding wheel. The efficiency of this method is low, but its quality is relatively good, and compared with similar products compared to the roughness is relatively low. During grinding, the rotation of the diamond grinding wheel is very high, and no process is in rotational motion. The workbench is a composite vertical operation, in each operation or process in the grinding wheel will have a resupply, the extra things will be touched off.

2.grinding skills. Also known as cross-grinding. This and the previous relative comparison is very high efficiency, the same it also has shortcomings, its grinding force is very large, and the temperature is relatively high, so in the grinding time to have enough cold solidified liquid. The rotation of the diamond grinding wheel is a kind of active force, the rotation movement of the process and the movement of the grinding wheel leads to continuous replenishment. The workbench of the grinding wheel will not have vertical operation of the movement, the width of the diamond grinding wheel and the width of the grinding will be relatively large, until grinding to the used size.

3.compound grinding skills. This is a combination of the two above. The efficiency of composite grinding and grinding method is relatively high and the quality is relative, and it is better, and there are certain advantages in other advantages. When grinding, we have to use the form of segmented grinding, the rest with grinding plate treatment.

4.there is another method is a deep grinding method. Its production efficiency is very high, but the grinding wheel dressing technique is more complex, the overall structure requirements of the workpiece is relatively high, to have sufficient cut and cut out length. While grinding. The entire section of the grinding wheel will have a ladder shape. The speed and means of the workpiece are very slow. Use longitudinal grinding in grinding the rest.

<< Prev Article:Why Do machine Tools Release Stress?

<< Next Article:150D 4-Axis CNC PCD&PCBN Tool Grinder

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220