what is turning?

Turning is to change the shape and size of the blank by using the rotary motion of the workpiece and the linear or curved motion of the tool on the lathe, and process it to meet the requirements of the drawing.

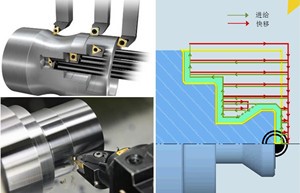

The characteristics of transverse turning:

1.In transverse turning, the direction of movement of the turning tool is parallel to the axis of rotation of the workpiece.If it is a main spindle, the tool moves from right to left; if the machine has a sub-spindle, the tool moves from left to right.

2. Larger transverse feed can be realized, that is, larger chip cross-sectional area.

3.High feed rate can be achieved in rough machining

4.Perfect chip discharge effect

5.Transverse turning can be used to process external circles and internal holes, but when machining internal holes, a bottom hole must be pre-drilled first. In addition to machining outer circles, end faces can also be machined.

6. Not all profiles can be transversely turned with a limited number of tools, and more tools may need to be replaced during machining.

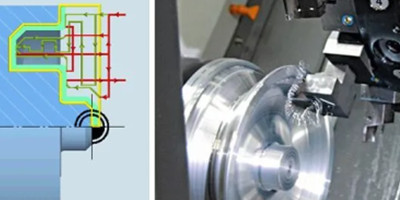

The characteristics of longitudinal turning:

1.When performing longitudinal turning on the side of the workpiece, the feed direction of the slitting turning tool is perpendicular to the axis of rotation of the workpiece. • In longitudinal turning of the workpiece end face, the feed direction of the slitting turning tool is parallel to the workpiece axis. + Avoid empty cutting stroke

2. Reduced tool changing operation

3. A high degree of flexibility in applications

4. Not all profiles can be machined due to tool limitations

5. Chip discharge is sometimes less than ideal (chips may become stuck)

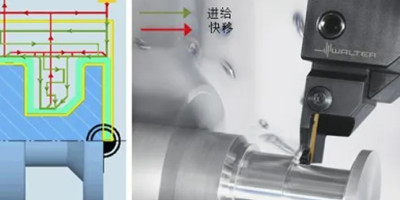

When to use longitudinal turning and when to use transverse turning?

Longitudinal turning is generally used for machining parts with deep grooves and 90° corner structures, which can only be machined by this process.

Transverse turning is generally used for streamlined profile structures with arc transitions.

Common turning tool materials

High-carbon steel, high speed steel, Tungsten steel cutter,l Non-cast iron alloy tools, Sintered carbide tool ,Ceramic Turning Tool, Diamond cutter ,CBN tools,PCBN tools

Moresuperhard is a diamond grinding wheel manufacturer from China.

Moresuperhard provide all set grinding solutions for various turning tools including PCD turning tools ,PCBN turning tools,carbide turning tools,ceramics turning tools.

Moresuperhard provide vitrified diamond grinding wheel for precision PCD turning tools and resin bond diamond grinding wheel for CBN turning tools.Moresuperhard also supply PCD grinding machine including MT198NC and BDM-902 grinding machine.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088