Vitrified grinding disc is made of grinding disc matrix and super hard diamond grinding pellets by epoxy resin adhesive, and can be made into various shapes such as regular hexagon, sector, square ,circular, trigonometrical, hexagonal pellets (other shapes can be customized). Vitrified grinding disc is made of grinding disc matrix and super hard diamond grinding pellets by epoxy resin adhesive, and can be made into various shapes such as regular hexagon, sector, square ,circular, trigonometrical, hexagonal pellets (other shapes can be customized).

Moresuperhard offers a full line of diamond and CBN grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems.

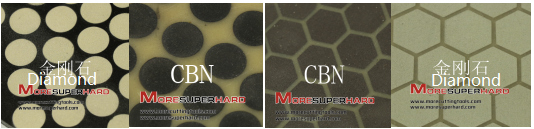

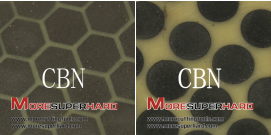

The diameter of the round pellet is 20-35mm thick and 5-10mm. The glue joint is too sharp to grind small workpieces, while for Hexagon pellets, length 13mm thick 5-10mmand with a smaller glue joint (2mm) can get better wear resistance.

Vitrified superhard grinding disc can be divided into vitrified diamond grinding disc (the color of diamond pellets are white and yellow) and vitrified CBN grinding disc ( the color of CBN pellets are black or brown).

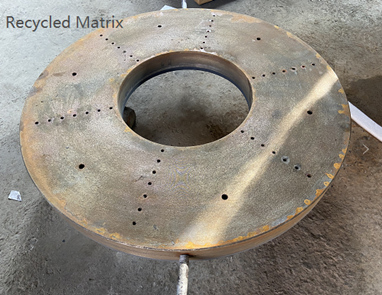

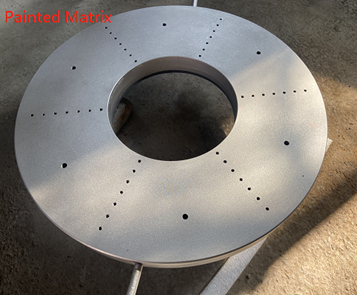

Take the 650mm diamond disc for example(the matrix is recycled from a customer):

There are 42 water holes and 6 connecting holes on the surface of the matrix (all in the upper plate and none in the bottom platel). Also there are 4 symmetrical serial loading holes on the periphery, and the matrix can be recycled (generally at least 50 times).To make recycled matrix look good, it will be painted before packing.

Moresuperhard Diamond/CBN grinding discs are widely used for grinding the surface, suitable for steel, cast iron, copper, carbide,PCD/PCBN inserts, hard alloy, ceramics, monocrystalline silicon and other processing. It can be widely used in hydraulic pneumatic components, hydraulic motor parts, automobile fuel pump parts, refrigeration compressor parts, oil pump oil.

Accuracy of finished workpiece:

roughness 0.1um-1.2um

Flatness: 0.001mm ~ 0.004mm

Parallelism: ≤0.002mm

Equal height: ≤0.002mm.

Applicable equipment: Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other DDG machines.

Moresuperhard can also provide matching dressing grinding wheel of DDG wheel:

According to the different particle size, accuracy of the diamond and CBN grinding disc to choose the dressing wheel, making dressing easier and more time saving. Mostly we use are silicon carbide(GC) dressing wheel while diameter is 205mm, grit 180#.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088