Single crystal diamond tools are almost exclusively used for high-precision finishing, which can ensure extremely high dimensional accuracy. PCD and CVD diamond can be used in many of the same processing fields, and PCD is more suitable for rough machining and processing occasions that require high tool fracture toughness. CVD diamond is better at finishing, semi-finishing and continuous turning, and can process more precise workpieces.

|

Performance |

MCD Tools |

CVD Tools |

PCD Tools |

|

Material structure |

Diamond |

Diamond |

Co-containing adhesive |

|

Abrasion resistance |

Higher than PCD and diamond film |

2-10 times higher than PCD |

Varies with diamond particle size |

|

Toughness |

Bad |

Good |

Excellent |

|

Chemical stability |

High |

High |

Lower |

|

Machinability |

Bad |

Bad |

Excellent |

|

Solderability |

Bad |

Bad |

Excellent |

|

Cutting edge quality |

Excellent |

Excellent |

Good |

|

Applicability |

Super finishing |

Finishing, semi-finishing, continuous cutting, wet cutting, dry cutting |

Rough machining, finishing |

PCD tools are most suitable for processing aluminum and other tough non-ferrous alloys (such as copper, brass, and bronze), as well as highly abrasive composite materials (such as graphite, carbon-carbon materials, carbon-added phenolic, glass fiber, and porous seals material).

Single crystal diamond tools are almost exclusively used for high-precision finishing, and their extremely thin cutting capabilities can ensure extremely high dimensional accuracy. PCD and CVD diamond can be used in many of the same machining areas, but PCD is more suitable for rough machining and machining situations that require high tool fracture toughness. CVD diamond is better at finishing, semi-finishing and continuous turning. This is because it has excellent wear resistance and high hardness, and can process more precise workpieces.

(1)The condition of polycrystalline PCD and single crystal diamond under a metallurgical microscope, the lower left picture clearly shows that the edge of the blade will be jagged, while the right picture is smooth and smooth.

PCD under the microscope 100 times:

MCD under the microscope 100 times:

(2) Differences in processing:

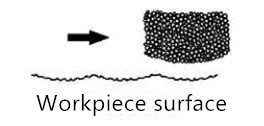

PCD tools are composed of many fine crystals, so when turning processing, the surface of the workpiece will also show traces caused by small crystal grains.

MCD cutter can directly present the perfect state of the blade on the workpiece.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088