In recent years, everyone must be familiar with carbon fiber composite materials. Carbon fiber composite material is ubiquitous in all kinds of science fiction, racing movies. Such as the 350Z body in the Tokyo Drift “The Fast and the Furious Ⅲ”, the wings of the falcon in "Avengers", the torso of the Baymax in "Big Hero 6" are all made of carbon fiber materials.

In real life, carbon fiber composite materials are also widely used in aerospace, automobile, rail transit, sports goods and other fields.

So how did carbon fiber composite material become a hot material nowadays? What are its advantages? Next, let’s take the aviation industry as an example to introduce you.

Lightweight, high strength and weight reduction

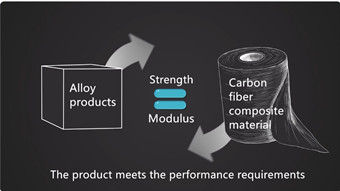

Carbon fiber composite material has strong mechanical properties, and its specific strength and specific modulus are many times higher than other aerospace alloys with similar functions. In other words, under the same tensile strength and tensile modulus, when the product meets the performance requirements, the weight of carbon fiber products is much lower than that of alloy products.

This advantage can be transformed into a significant weight reduction effect, which can increase the weight of the aircraft, extend the range, and save energy. It should be understood that the value of 1 gram of weight loss on an airplane can be much greater than 1 gram of gold. Experts in the industry point out that every 1 kilogram of the airplane’s weight is reduced, which is equivalent to an increase of 5 million US dollars in economic benefits.

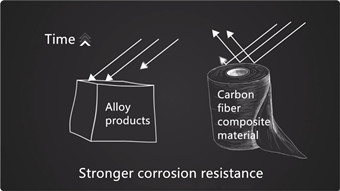

Stability

The stability of carbon fiber composite is reflected in corrosion resistance, fatigue resistance and other properties. For long-distance flights, the wind and sun are inevitable. Sulfides in the air and various acid and alkali substances in rainwater are constantly eroding the surface of the aircraft. Carbon fiber composites have stronger corrosion resistance and fatigue resistance than alloys, and have better economic benefits. Reduce the lifetime cost of the aircraft.

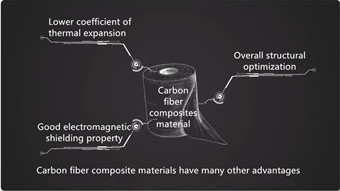

In addition, carbon fiber composite materials have many other advantages. For example, with a low coefficient of thermal expansion, the fuselage of an aircraft is less prone to deformation due to changes in temperature. The overall structure is optimized to reduce the number of components used to assemble the aircraft, which reduces the workload and improves efficiency; The electromagnetic shielding performance is good, so that the aircraft has better stealth performance when performing missions and is not easy to be found.

These superior properties have helped carbon fiber composite materials to be widely used in the aviation field and become the new favorite of the aviation field.

"More Super Hard” is committed to providing customers with the most advanced, efficient and economical products in order to meet more customer needs.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088