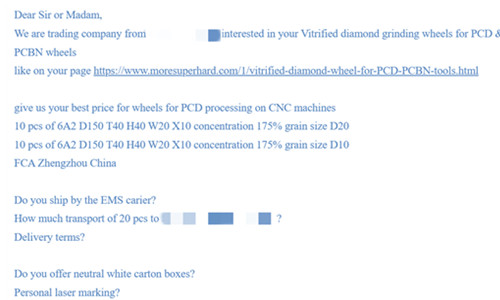

First of all we received an email from customer,the content as follws:

We are interested in your Vitrified diamond grinding wheels for PCD & PCBN wheels on EWAG RS15 with coolant.

like on your pagehttps://www.pcdgrinding.cn/grinding/Vitrified-diamond-grinding-wheels-for-PCD.html

give us your best price for wheels for PCD processing on CNC machines 在 6A2 D150 T40 H40 W20 X10 concentration 175% grain size D20

6A2 D150 T40 H40 W20 X10 concentration 175% grain size D10

According to customer's requirement,our professional technician replied our solutions by email

1.What to use to sharpen PCBN (CBN cutters) ?

May I know the PCBN tools you want to grind? if you can send us the pictures that will be better.

We have a special formula of resin bond diamond wheels to sharpen CBN tools while grit W35.

resin bond 6А2 D150 W20 X10 40 H40 D20

2.May I know the requirements of chipping of inserts by using the wheel 6А2 D150 W20 X10 40 H40 D10 (8-12 mikron)?

Chipping means the edge quality you want to get. That is ok, we will make it 8-12 microns.

Customer's confusion and our replys

clients:Which grit you have D3 or D4?

replys:6А2 D150 W20 X10 40 H40 for grinding MCD we make is D3.

clients:why do you machine radialpart of 6A2 to decrease W size?

replys:Usually wheels are machined on flat sizes,so X or T can be changed

-----This is not the same thing. As original mould is W6mm, after diamond layer press and burn in the stove, it will produce shrinkage during the production, and to make the diamond layer clean we should grind it so actually layer width is 5mm, which is also standard in market. That is no change of as till now seldom use W=6mm. To promise the accuracy 5mm we should order 6mm mould with tolerance. Anyway, we need W=6 mm Please quote us W=6 mm , if you insist on this, we can make new mould for you. 6А2 D150 W6 X10 40 H40,D20 for grinding PCD Actually W5 is ok for your clients, as this is standard sizes, but we respect your idea.

clients:Why our price is higher than them?

replys:As we all know in the market their is no doubt that some factories who make and seel this kind of wheel at very low price. Before our production of a wheel, we select diamond power materials and choose the most suitable particle type for making pcd grinding wheel. When production our Geometric Tolerance is controlled strictly. So is appearance and dynamic balance. That is why our price is higher than them, we use better materials and machining, we promise each wheel we sent to our customers is in a good performance.

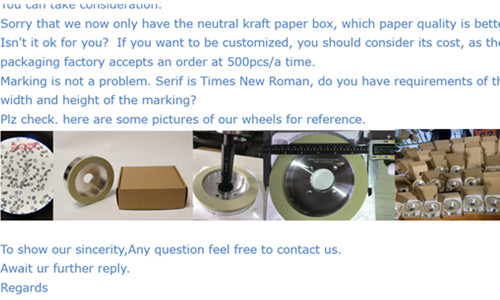

Moresuperhard also provide dressing solutions for customer

For dressing we suggest you also use vitrified diamond wheels if possible. Of course we also have softer dressing sticks. for dressing 6А2 D150 W20 X10 40 H40 grit size D3 for MCD please put into a parcel aluminum oxide honing stone (WA) 150-25-25 with grits 400 #, 500 #, 800 #, 1000 #.

<< :CVD Tools Ginding Services From Moresuperhard

<< :Polishing knowledge-1.Common polishing methods and working principles

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088