CVD diamond - a new super heat dissipation material for fever reduction. Due to its extreme qualities, polycrystalline CVD diamond has long been considered the ultimate material in a variety of applications. CVD diamond unmatched hardness is demanded by complex tools and machining processes around the world. The high thermal conductivity of diamond makes it very useful in thermal management applications. Its broad optical transmission range enables diamond windows to enter cutting-edge, future-generation semiconductor fabrication lithography systems. Furthermore, its transparency in the microwave band opens up a whole world of application development in microwave engineering. In its purest form, polycrystalline CVD diamond has no electron traps, making it an ideal material for ultrasensitive nuclear detectors used in high-energy applications.

As a representative of the above materials, CVD diamond film has a thermal conductivity of more than 2000W/(n. K), and also has excellent mechanical, optical, electrical, acoustic and chemical properties. Compared with natural diamond, the structure is consistent and the performance There is basically no difference, and the cost is low, which makes its advantages in heat dissipation of high-power optoelectronic devices significantly higher than other materials. At present, CVD diamond has been applied in thermal management at home and abroad, mainly to solve the system heat dissipation problem caused by high-power and high-heat flux components, including high-power laser diode arrays, three-dimensional multi-chip assembly (MCM) and solid-state microwave power devices. cooling applications. Unmetallized CVD diamond heat sinks cost $1 per cubic millimeter to mass produce, and the price depends primarily on the thermal conductivity grade. For applications with common thicknesses between 0.25-0.40mm and lateral dimensions equal to wafer size, RF device diamond heat sinks are typically less than 5mm3 in size. Therefore, only a few additional dollars in incremental cost at the chip level can significantly reduce system cost. For example, enabling the system to operate at higher temperatures can reduce both the initial cost of cooling the subsystem and the ongoing cost of operation thereafter. With the proper die attach method, diamond heat sinks provide a reliable thermal management solution for semiconductor packages.

What is CVD diamond?

CVD diamond is a kind of all-crystalline polycrystalline pure diamond material prepared by chemical vapor deposition method, which is an ideal material for preparing cutting tools. CVD diamond knives have unique mechanical, thermal and chemical properties that are at or close to natural diamond. It has excellent thermal conductivity, hardness, wear resistance and chemical inertness, very low coefficient of friction and coefficient of thermal expansion. CVD diamond tools do not add any metal binder, have high purity, and have a heat resistance of up to 1000 °C. Not only is the cost low, but also tools of any shape can be manufactured.

What are the applications of CVD diamond plates/ blades?

CVD diamond include multispectral laser optics, dielectric windows, heat sinks, and more.

- Cutting tools for cutting cemented carbide, copper and copper alloys, aluminum alloys and other non-ferrous metal engineering plastics, composite materials, ceramics, glass, graphite wear-resistant parts

- For dressing brown corundum and silicon carbide wheels, diamond wheels, vitrified bond CBN wheels

At present, CVD diamond blades are mainly divided into two categories, one is CVD diamond film coating tool, which directly deposits a diamond film of no more than 50 μm on the tool, which is especially suitable for processing non-ferrous metals and their alloys, non-metallic materials, composite materials, etc. Difficult-to-machine materials; the other type is CVD diamond thick film welding tool, which cuts diamond thick film with a thickness of more than 0.1mm into small pieces and then welds them on the tool holder for precision or even ultra-precision cutting. The diamond thick film uses the electron-assisted hot wire CAD method (EACVD), the growth rate of the diamond film reaches 10μm/h, the diameter of the thick film is less than 120mm, the deposited diamond film has a dense structure, and the content of amorphous carbon and graphite is very small.

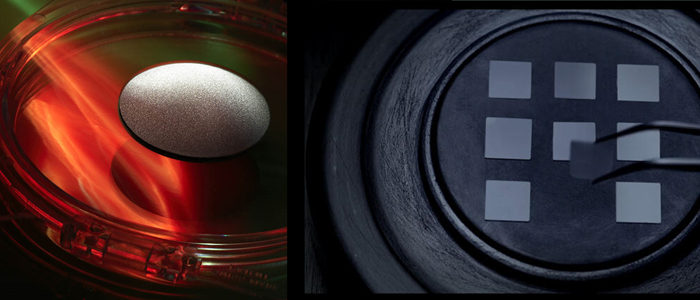

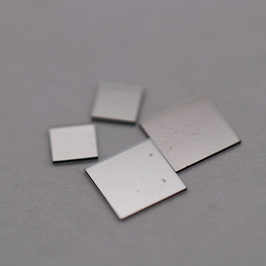

Customer case of CVD Diamond

|

1.Size: 4.5x4.5x0.5mm thickness Electron optical grade 2. The crystal orientation error is plus or minus 3° 3. Crystal phase: upper and lower (100) side (110) 4. Laser cutting cutting error <0.02 mm Laser cutting angle <5°° 5. Thickness error +/- 0.05 mm 6. Surface roughness polishing Ra < 30 nm 7. Boron concentration <1 ppb 8. Nitrogen concentration < 5 ppb (usually the nitrogen content of crystal diamonds is ppb level, generally less than 100ppb level, nitrogen concentration < 5 ppb |

|

<< :How to process gold jewelry with single crystal tool

<< :What role does brazing welding play in the manufacture of PCD tools?

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088