Method of external grinding

2019-11-15 10:16:13

.jpg)

.jpg)

Method of external grinding

The longitudinal grinding method is the most commonly used grinding method. During grinding, the table is fed longitudinally and reciprocally, and the grinding wheel is fed periodically. The grinding allowance of the workpiece is ground in multiple reciprocating strokes.

-Form of external grinding

1. Center type cylindrical grinding

2. Centerless cylindrical grinding

3. Face external grinding

-Grinding method of outer circle and step surface

1. Method of external grinding

(1) longitudinal grinding method

The longitudinal grinding method is the most commonly used grinding method. During grinding, the table is fed longitudinally and reciprocally, and the grinding wheel is fed periodically. The grinding allowance of the workpiece is ground in multiple reciprocating strokes.

Characteristics of longitudinal grinding method:

1) The working condition of the abrasive grains is different in the whole width of the grinding wheel. The sharp end of the left end surface (or the right end surface) of the grinding wheel bears the main cutting action, and the grinding allowance of the workpiece part is removed by the abrasive grains at the sharp corner of the grinding wheel. Most of the abrasive grains on the width of the grinding wheel are responsible for reducing the surface roughness of the workpiece. The longitudinal grinding method has small grinding force and good heat dissipation conditions, and can obtain high processing precision and small surface roughness value.

2) Low labor productivity.

3) Small grinding force, suitable for grinding of slender, precision or thin-walled workpieces.

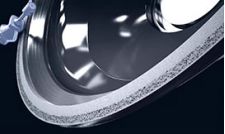

(2) cutting into grinding method The plunge grinding method is also called the transverse grinding method. The length of the outer circle of the workpiece to be grounded should be less than the width of the grinding wheel. When grinding, the grinding wheel should be continuously or intermittently fed in the transverse direction until the entire amount is removed. There is no longitudinal feed motion during grinding of the grinding wheel. A higher cutting speed can be used for rough grinding; a lower cutting speed for fine grinding to prevent burns and deformation of the workpiece.

The characteristics of the plunge grinding method (referred to as the cutting method):

1) The working condition of the abrasive grains on the entire width of the grinding wheel is the same, and the grinding effect of all the abrasive grains is fully exerted. At the same time, since the continuous lateral feeding is used, the basic time of grinding is shortened, so that the production efficiency is high.

2) The radial grinding force is large, the workpiece is prone to bending deformation, and it is generally not suitable for grinding fine workpieces.

3) A large grinding heat is generated during grinding, and the workpiece is easily burned and deformed.

4) The shape of the surface of the grinding wheel (trimming marks) will be copied to the surface of the workpiece, affecting the surface roughness of the workpiece. In order to eliminate the above defects, a slight longitudinal movement can be made at the end of the cutting method. 5) The cutting method is limited by the width of the grinding wheel and only applies to the outer surface of the grinding length.

(3) Segment grinding method The segmented grinding method is also called the comprehensive grinding method. It is a comprehensive application of the cutting method and the longitudinal method, that is, the workpiece is first coarsely ground by the cutting method, leaving a margin of 0.03 - 0.04 mm, and finally refined to the size by the longitudinal method. The grinding method utilizes the advantages of high productivity of the cutting method and high precision of the longitudinal processing. For segmental grinding, there should be an overlap of 5-10 mm between adjacent sections. This grinding method is suitable for grinding workpieces with good balance and rigidity, and the length of the workpiece is also appropriate. Considering the grinding efficiency, a wider grinding wheel should be used to reduce the number of segments. It is optimal when the length of the machined surface is about 2-3 times the width of the grinding wheel.

(4) Deep grinding method This is a more abrasive method that uses a larger back-feeding amount to grind all of the workpiece's grinding allowance in a single longitudinal feed. Since the basic time for grinding is shortened, labor productivity is high.

Features of deep grinding:

1) Suitable for grinding rigid workpieces

2) The grinding machine should have greater power and stiffness.

3) Smaller one-way longitudinal feed is used for grinding. The longitudinal feed direction of the grinding wheel should face the headstock and lock the tailstock sleeve to prevent the workpiece from falling off. The hardness of the grinding wheel should be moderate and have good grinding performance.

2. Stepping surface grinding method

The step surface of the workpiece can be ground by hand on the work surface by the grinding wheel after grinding the outer circle. When grinding, the grinding wheel should be slightly pulled out laterally, and the worktable should be hand-held. After the grinding wheel is in contact with the end surface of the workpiece, make intermittent feed, and pay attention to pouring sufficient cutting fluid to avoid burning the workpiece. Generally, the end surface of the grinding wheel can be modified into a concave shape to reduce the contact area between the grinding wheel and the workpiece, and improve the grinding quality.

<< Prev Article:Vitrified bond diamond grinding wheel for PDC cutter

<< Next Article:What Woodturners Need to Know about CBN (Cubic Boron Nitride).

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220