Because professional, so excellent. Moresuperhard provides our customers not only products, but a complete set of tool machining technology solutions.

We always believe that advanced production and testing equipment is a powerful guarantee for the manufacture of high-quality tools. Today, let's take a brief look at several internationally well-known grinding machines.

1. VOLLMER Machine Tool In Germany

The VHybrid 260 tool grinder from VOLLMER, Germany, combines an innovative sharpening machine with a powerful EDM machine – and can switch between the two functions at short notice. Significantly improved efficiency and economy when machining rotary carbide and PCD tools up to 150 mm in diameter. The V Grind 260 has everything you need to fully machine rotary tools. Ideal for the combination of tool sharpening and EDM in industries such as automotive engineering, tool making, medical technology, precision engineering and aerospace.200% increase in production efficiency and optimal tool surface and edge quality: extremely fine and high-precision EDM pulses can achieve a surface roughness of Ra 0.1 (depending on tool type), HYBRID technology ensures efficient tools Sharpening and EDM.

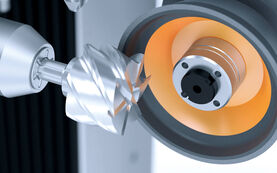

2. COBORN RG Series Grinder

The COBORN RG9 is a fully automatic high-precision grinding machine designed to meet the complex demands of tool machining in hard and superhard materials such as carbide, ceramic, cermet, PCD and PCBN. The construction of the RG9A ensures fast grinding times and repeatable accuracy down to 2µm tolerances. Grinding wheel spindles designed and manufactured by Coborn are dynamically balanced to ensure minimal edge chipping in brittle and precision tool materials.

3. EWAG High Precision Tool Grinder

EWAG High Precision Indexable Insert Machining Multipurpose Grinder CNC Tool Grinder with six CNC axes. Tool grinders are used for the production of indexable inserts including deburring, milling, turning and forming plates suitable for peripheral grinding.EWAG tool grinder can process tool materials: carbide, cermet, ceramic, cubic boron nitride, polycrystalline diamond Grinding.

Spindle Power: 12KW

Wheel Diameter: 350-500mm In-machine grinding wheel dressing, in-machine tool measurement

Granite bed, hydrostatic guide

Maximum axis moving speed: 30m/min Compact machine structure (W*H*D: maximum 3*2*3m)

Unique power transmission: All axes are directly driven (torque transmission of the rotary axis and direct drive of the linear motors of the X and Y axes) to ensure high precision and stability of the grinding process, and also to ensure high power .

4. Anca Tool Grinde in Australia

The Australian Anka Tool Grinder X7 is a small and compact machine, but it has a large grinding area and is suitable for various types of tool processing with different geometries.In addition to grinding, it can also take into account production. Anca MX7 high-precision CNC grinding machine meets the needs of high-production, high-precision machining tools.

5. German Walter Tool Grinder

The HELITRONIC POWER 400 tool grinder from Walter in Germany is powerful and offers maximum flexibility for medium to large series tool machining.Walter represents the highest quality in the production and grinding of rotationally symmetrical tools worldwide.It can grind tools with diameters ranging from 3 to 315 mm, machining lengths up to 520 mm and a single piece weight of up to 50 kg.

6.Romantic CNC machine in Switzerlandgrind .Grind smart series grinder is specialized in processing rotary tools

Romantic grind smart series high-precision CNC grinding machines are used for grinding micro-diameter tools, 6-axis linkage.

Moresuperhard can provide a complete set of high-quality tool machining technical solutions, including not only the choice of grinding machines, but also grinding consumables suitable for the above equipment.

Moresuperhard is committed to the development and production of superhard material grinding wheels including diamond and CBN grinding wheels.

Moresuperhard has developed grinding wheels with different bonding agents according to the characteristics of tool materials, including ceramic bonds, metal bonds and resin bonds.

Moresuperhard can provide cutting tools grinding wheels for carbide tools, ceramic tools, cermet tools, single crystal tools, PCD tools and CBN tools manufacturers.At the same time, Moresuperhard provides dressing services for cutting tools grinding wheels. The dressing products mainly include vitrified diamond dressing wheels, diamond dressing pens, white corundum dressing wheels, silicon carbide dressing wheels, etc. to help customers solve grinding wheel dressing problems in different production conditions.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088