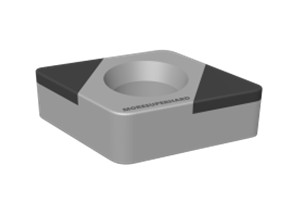

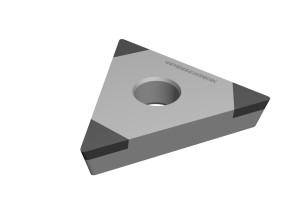

Indexable inserts: the new trend in precision cutting

Indexable inserts, as the mainstay of the metal cutting field, are ushering in a golden age of development.

1. Digital manufacturing and automation trends: As manufacturing becomes more digitalized and automated, indexable inserts are also evolving. Using advanced CNC technology, tool manufacturers can produce more precise and efficient indexable inserts to meet diverse cutting needs.

2. Innovative materials and designs: Modern machining requires materials that can withstand high temperatures, speeds and changing cutting conditions. Trends in indexable inserts involve the use of advanced materials such as ceramics, polycrystalline diamond (PCD) and cubic boron nitride (CBN). These materials extend tool life, improve wear resistance, and enable the machining of hard and specialty materials

3. Sustainable manufacturing: As the focus on sustainable development increases, the focus on energy efficiency, material recyclability and other aspects when producing indexable inserts has driven the development of this field in a more sustainable direction.

Peripheral Grinding Wheels: The Way to Perfection

Peripheral grinding wheels, as a sharp grinding tool in the processing field, are ushering in a broader market.

1. Grinding of superhard materials: With the application of emerging materials, peripheral grinding wheels have outstanding performance in grinding superhard materials. The use of superhard materials such as diamond and boron nitride makes the grinding process more efficient and precise.

2. Intelligent grinding system: Introducing artificial intelligence and Internet of Things technology to realize real-time monitoring and control of the grinding process. This helps increase production efficiency, reduce energy consumption, and lower equipment maintenance costs.

3. Customized solutions: Tool manufacturers are increasingly focusing on providing customers with customized grinding solutions to meet the needs of different industries and applications. This promotes the wide application of peripheral

grinding wheels in many fields.

The road to the future: Innovation leads the manufacturing trend

Indexable inserts and peripheral grinding wheels, as two major tools in the manufacturing industry, will continue to integrate innovation in the future and lead the trend of the manufacturing industry.

1. Interconnection: It is expected that in the future, indexable blades and peripheral grinding wheels will be better interconnected. Through intelligent technology, they can work better together to achieve more efficient processing processes.

2. Sustainability: Manufacturers will continue to pursue more environmentally friendly and sustainable manufacturing processes. From material selection to production processes, indexable inserts and peripheral grinding wheels are moving in a more sustainable direction.

3. High-precision processing: As demand continues to increase, indexable inserts and peripheral grinding wheels will develop towards higher-precision and higher-efficiency processing to meet the pursuit of workpiece quality and production efficiency in different industries.

Moresuperhard diamond peripheral grinding wheel

As a supplier of superhard tool grinding solutions, Moresuperhard has been providing customers with high-quality ceramic diamond peripheral grinding wheels for grinding PCD/PCBN indexable inserts. With the market development of indexable inserts, Moresuperhard developed resin diamond peripheral grinding wheels can be used for grinding PCBN/ceramic/cermet carbide indexable inserts, etc. Moresuperhard provides customized peripheral grinding wheels that can be adapted to well-known peripheral grinding machines such as Hypertherm, Hautemann, Agathon, Ewag, Wendt, Waida, etc.

<< :Single Crystal Diamond Tools Grinding Case

<< :Application of Diamond in new electronic packaging substrate

Moresuperhard single-crystal diamond heat sinks offer ultra-high thermal conductivity (>2000 W/m·K), excellent electrical insulation, and a lightweight design, making them ideal for 5G, high-performance computing, RF power devices, semiconductor lasers, and aerospace applications.

Discover the key to optimizing single-crystal diamond tool performance with the right crystal face selection. Learn about (100) and (110) faces, their applications in precision machining, metal cutting, and semiconductor processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088