PCD and CBN cutting tools are widely used in metal cutting and processing nowadays. The quantity demanded has a 20 times increased in last 5 years. To fit the social more complex needs and rapid development of science and technology, tools manufacturer’s demands for higher precision and better grinding efficiency are also increasing as well. “More Super Hard Products” devotes to offer an efficiency and economic solution in PCD and CBN cutting tools grinding.

Improved Bond Systems

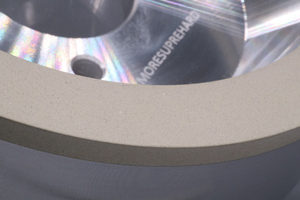

Besides choice of the correct diamond girt, the bond system is the key to get superior grinding result. Great effort is made to innovate and improve the previous bond system. Several exclusive bond system lines (no porosity series, high porosity series) are offered to meet different grinding purpose.

Super-Fine Girt Size Available

With the demand of extremely smooth cutting edge, we recommend super-fine grit size wheel to customers. D3(4000#) and D7(3000#) grit size now are available, they provide you superior cutting edge chipping <5 μm.

Features Of Vitrified Bond Diamond Grinding Wheel For Pcd Cbn Tool Grinding

Shorter set-up times

Easy to dress

Stable grinding performance based on improved bond system

Cutting-edge chipping <5 μm through the use of super-fine grit size

Multiple bond systems aim at different working condition

Recommended Parameter

Grinding wheel speed ---- 14 ~ 26 m/s

Dressing wheel speed ---- 6 ~ 26 m/s

Dressing amount ;---- 0.02 ~ 0.05 mm

Oscillation ; ---- 10 ~ 120 passed/min

|

Grinding machine |

EWAG EasyGrind |

|

Coolant |

Emulsion |

|

Workpiece |

PCD insert (brazed, include carbide ) |

|

Grinding Parameters |

|

|

Feed Rate |

Vf = 2mm/min |

|

Stock |

0.3mm |

|

Cutting Speed |

Vc=15m/s |

|

Advantage |

|

|

1, 35%-time savings |

|

|

|

|

Diamond wafers have great potential in high-end fields such as quantum computing, microwave power devices, and semiconductor lasers due to their ultra-high hardness, excellent thermal conductivity, and wide bandgap properties.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088