Suitable for preparing emission windows

laser crystals of high-power lasers

lenses of high-power UV/infrared optical instruments

sensors and detectors that need to work in harsh environments

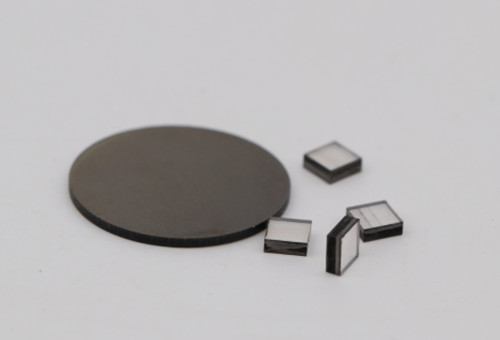

CVD diamond for optical windows

CVD (Chemical Vapor Deposition Diamond) Diamond Optical Windows are high-performance materials designed for demanding optical and infrared applications. They combine excellent mechanical strength, wide spectral transparency and high thermal conductivity, making them ideal for modern high-tech optical systems.

Key Features of CVD diamon optical window

Broad Spectral Transparency :High transmittance from UV to far infrared (225 nm - 50 μm). Suitable for a variety of optical applications, including laser and infrared imaging.

High Thermal Conductivity :Thermal conductivity is up to 2000 W/m·K, which can effectively dissipate heat and prevent thermal damage.Suitable for applications in high-power lasers and high-temperature environments.

Excellent Mechanical :Strength Extremely high hardness and wear resistance, able to withstand harsh environments and mechanical stress. Extends the service life of optical windows.

Chemical Inertness: Highly resistant to most chemical reagents, suitable for use in harsh chemical environments. Ensures stability and reliability under long-term use.

CVD diamond optical windows specifications

| Paraments | Specifications |

| Materials type | CVD synthetic diamond |

| Sizes | within 10*10*2 |

| Transmittance range | 225 nm - 50 μm |

| Optical transmittance(1mm thickness) | 60%-71% |

| Thermal conductivity | Up to 2000 W/m·K |

| Refractive index | 1064nm:2.392; 600nm:2.415 |

| Chemical stability | Highly resistant to most chemical agents |

Applications of CVD diamond plate for optical windows

High-power laser systems

Protective windows for high-power lasers and laser processing equipment. Infrared spectrometers Provide excellent optical performance from UV to IR, suitable for infrared spectroscopy analysis.

Aerospace

Applicable to windows for aircraft and spacecraft, capable of withstanding extreme temperature and pressure changes.

Military and security

Optical windows for military optoelectronic systems and security camera equipment, providing high transmittance and durability.

Scientific research

Applicable to a variety of scientific experimental equipment, including optical components in high-energy physics and material research.

Size and shape: Customization services of various sizes and shapes can be provided according to customer needs.

Coating: Various anti-reflection and protective coatings are available according to application requirements.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Double-end face grinding is a grinding process for efficient processing of the end faces of parts. This grinding process can grind various metal and non-metal workpieces through the cooperation of different fixtures, and can also reduce positioning errors and processing errors, ensuring high flatness of the workpiece and parallelism of the two planes. At present, in order to meet the higher market demand of modern industry, the quality of the double-end face grinding disc used in conjunction with it is particularly important.

Moresuperhard ceramic bond diamond grinding disc has superior performance in high alumina ceramic grinding. In the future, we will continue to be committed to providing customers with high-quality abrasive solutions to help them maintain their competitive advantage in the ever-changing market demands.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088