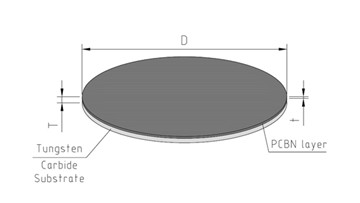

The standard shape of MORE® PCBN Cutting Tool Blanks is round. Other shapes, such as segment, rectangle, triangle, square, semi-circle and so on, can also be customized per customers requirements.

PCBN is widely used in processing of cast iron, hardened steel, powder metallurgy materials and Ni-Co heat-resistant alloy materials,

PCBN blanks for cutting tools is a kind of compound ultra hard material sintered by polycrystalline CBN and carbide alloy under the condition of ultra-high pressure and high temperature.

characteristic :

1.hardness,wear-resistance and thermal stability of CBN

2.impact resistance toughness of carbide alloy

3.fast cutting and high precision

Application:

Moresuperhard PCBN is ideal ideal material for cutting processing of ferrous metal and nonferrous metal with high hardness, such as harden steel, pearlitic gray cast iron, high temperature alloy, high-speed steel, hard facing alloys, Ni-Cr alloy, powder metallurgy metals. PCBN is typically used to machine brake discs, engine blocks, engine cylinder liners, brake drums, flywheels, valve seats and guides, gears, mold and die parts, etc.

Guidance of application

|

Material |

Material hardness |

Recommended Model |

Cutting speed V |

Feeding speed f |

Cutting depth |

|

|

(m/min) |

(mm/rev) |

(mm) |

||||

|

Cast iron |

Grey iron |

|

MBN91/90 |

600-1000 |

0.1-0.5 |

0.2-1.5 |

|

Alloy iron |

HRC59 |

MBN60/80 |

300-800 |

0.1-0.5 |

0.2-1.5 |

|

|

Ductile Iron |

>HB200 |

MBN60 |

100-500 |

0.1-0.4 |

0.1-0.5 |

|

|

Hardened steel |

Tool steel |

HRC60 |

MBN70 |

100-200 |

0.02-0.2 |

0.1-0.5 |

|

High-speed steel |

HRC63 |

MBN350 |

80-160 |

0.02-0.2 |

0.1-0.5 |

|

|

Bearing steel |

HRC60 |

MBN350 |

120-240 |

0.02-0.2 |

0.1-0.5 |

|

|

Powder metallurgy material |

Heat-resistant sintered alloy steel |

HRC45 |

MBN90 |

80-200 |

0.03-0.2 |

0.1-1.0 |

|

Iron-based sintered alloy |

HRC35 |

MBN90 |

100-200 |

0.03-0.2 |

0.1-1.0 |

|

|

Super-alloy |

Co-based |

HRC35 |

MBN91 |

50-100 |

0.05-0.2 |

0.1-1.0 |

|

Ni-based |

HRC36 |

MBN91 |

120-150 |

0.05-0.2 |

0.1-1.0 |

|

|

Iron-based |

HRC37 |

MBN91 |

130-150 |

0.05-0.2 |

0.0-1.0 |

|

|

Carbide |

Carbide |

|

MBN60 |

50-120 |

0.02-0.2 |

0.1-1.5 |

|

Item No.

|

Temperature Allowed

(℃) |

Wear-resistance

(SiC wheel) |

Bending Strength (Mpa) |

Vickers Hardness

(Hv) |

Electrical Conductivity |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MBN 90 |

1100 |

4200 |

1100 |

3100 |

Excellent |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MBN 91 |

1100 |

4800 |

1100 |

3600 |

Good |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MBN 80 |

1100 |

3900 |

1000 |

2700 |

Good |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MBN 70 |

1200 |

3500 |

900 |

2800 |

Excellent |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MBN 60 |

1200 |

3200 |

900 |

2800 |

Excellent |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MBN350 |

1200 |

3000 |

800 |

2600 |

Excellent |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note: customer specification available. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications

Product Measurement

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Double-end face grinding is a grinding process for efficient processing of the end faces of parts. This grinding process can grind various metal and non-metal workpieces through the cooperation of different fixtures, and can also reduce positioning errors and processing errors, ensuring high flatness of the workpiece and parallelism of the two planes. At present, in order to meet the higher market demand of modern industry, the quality of the double-end face grinding disc used in conjunction with it is particularly important.

Moresuperhard ceramic bond diamond grinding disc has superior performance in high alumina ceramic grinding. In the future, we will continue to be committed to providing customers with high-quality abrasive solutions to help them maintain their competitive advantage in the ever-changing market demands.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088