Cutting

Home / Cutting / PCD Cutting Machine > PCD PCBN Laser Engraving Machine

PCD Laser Engraving Machine

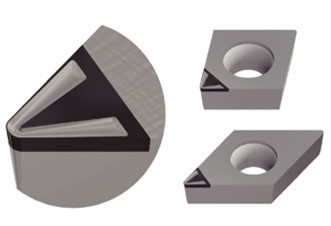

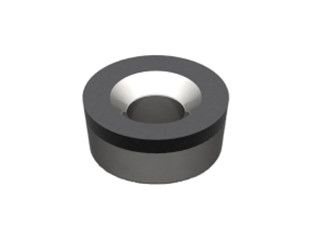

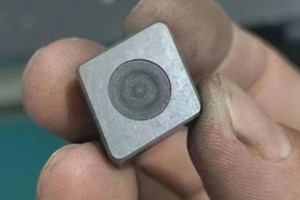

Applications:Locating groove, locating hole, breaking groove engraving for PCD/PCBN/CVD/ceramics

Laser Type:Nano fiber laser 100W

Automation software,Deep carving,Precision X, Y axis sliding table, can realize batch processing of materials

PCD Fiber Laser Engraving Machine characteristic

3D precision fiber laser engraving machine is a new processing method developed for the processing of special-shaped non-standard parts and other shapes of materials. The automation software will layer the 3D graphics to be processed, and realize laser layered precision processing through 3D galvanometers, so as to realize various materials. It is equipped with a coaxial vision system, which can realize the precise positioning of the processing position, and is equipped with a precise X, Y axis slide table, which can realize batch processing of materials.

Industry Applications

PCD fiber laser engraving machine can be used for engraving positioning grooves, positioning holes, and cutting grooves of superhard materials such as PCD, PCBN, CVD, and ceramics. It can also be used for 3D engraving of metal materials such as hard alloys, aluminum, and steel. It can also be used For precision cutting of thin sheet materials.

PCD Fiber Laser Engraving Machine Paraments

| Laser output power | NS fiber laser 100W |

| Repeat frequency | 1-4000KHz |

| Pulse width | 2-200ns |

| Type of cooling | ventilation cooling |

| Processing method | 3D scanning |

| Laser scanning range | 50*50mm |

| Heat influence range | ≤0.03mm |

| Maxium engraving depth on one side | 6mm |

| Table travel | 200*200mm |

| Repeat positioning accuracy | 0.002mm |

| The largest load | 15kg |

| Supply voltage | 220V 50Hz |

| Rated power | 1000W |

| External dimension | 1380*880*1800mm |

| Weight | 400kg |

Advantages of Moresuperhard PCD laser engraving machine

CCD Monitoring Online System, Accurate Positioning;

U.S. Original Laser Source, More Stable Performance;

One Button Operating Interface, Operation Friendly.

Standard 3D software input, combined parameter adjustment, one-key completion of roughing and finishing.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Double-end face grinding is a grinding process for efficient processing of the end faces of parts. This grinding process can grind various metal and non-metal workpieces through the cooperation of different fixtures, and can also reduce positioning errors and processing errors, ensuring high flatness of the workpiece and parallelism of the two planes. At present, in order to meet the higher market demand of modern industry, the quality of the double-end face grinding disc used in conjunction with it is particularly important.

Moresuperhard ceramic bond diamond grinding disc has superior performance in high alumina ceramic grinding. In the future, we will continue to be committed to providing customers with high-quality abrasive solutions to help them maintain their competitive advantage in the ever-changing market demands.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088